Diamond-Enabled, Reinventing the "Rigid Core" of Robotic Joints: The Revolutionary Application of DAOLER® Friction Washers in the Robotics Industry, Particularly in Joint Modules

Introduction: The Bottleneck of Robotic Evolution – The Pain of "Micro-Slip" in Joints

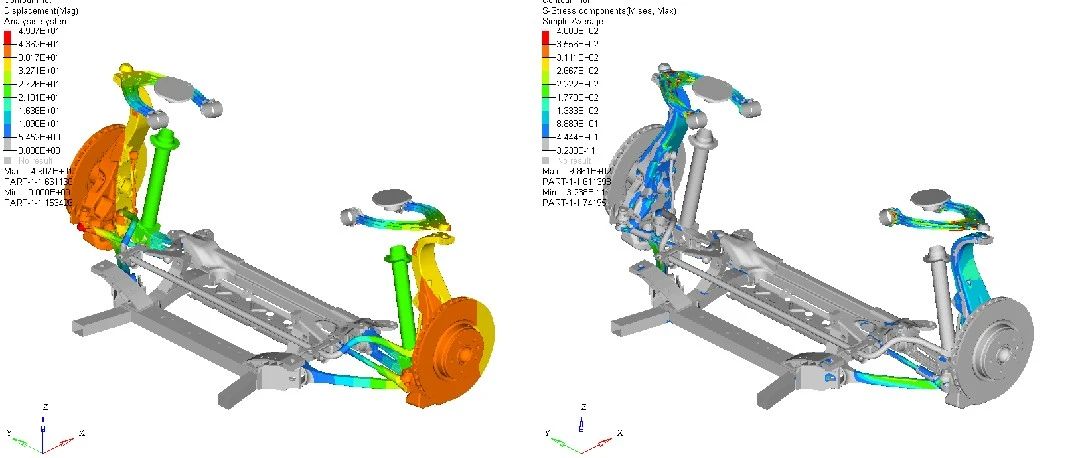

As industrial robotics advances towards higher precision, higher payload capacity, and higher cycle rates, while collaborative robots pursue lighter weight and smoother human-robot interaction, the performance of robotic joint modules has become a critical bottleneck defining their upper limits. During high-speed start-stop cycles, long-term reciprocating motion, and complex load variations, the issue of "micro-slip" – which traditional fastening solutions struggle to resolve – is quietly eroding robots' repeatability, dynamic response speed, and long-term reliability.

As experts in the robotics field, we believe that enhancing joint performance depends not only on motors and reducers but, crucially, on achieving a zero-slip, rigid connection between these core components and the structural frame. DAOLER®, with its unique diamond-embedded friction washer technology, provides a near-perfect solution to this industry pain point.

Part 1: The Core Challenges of Joint Modules and DAOLER®'s Solutions

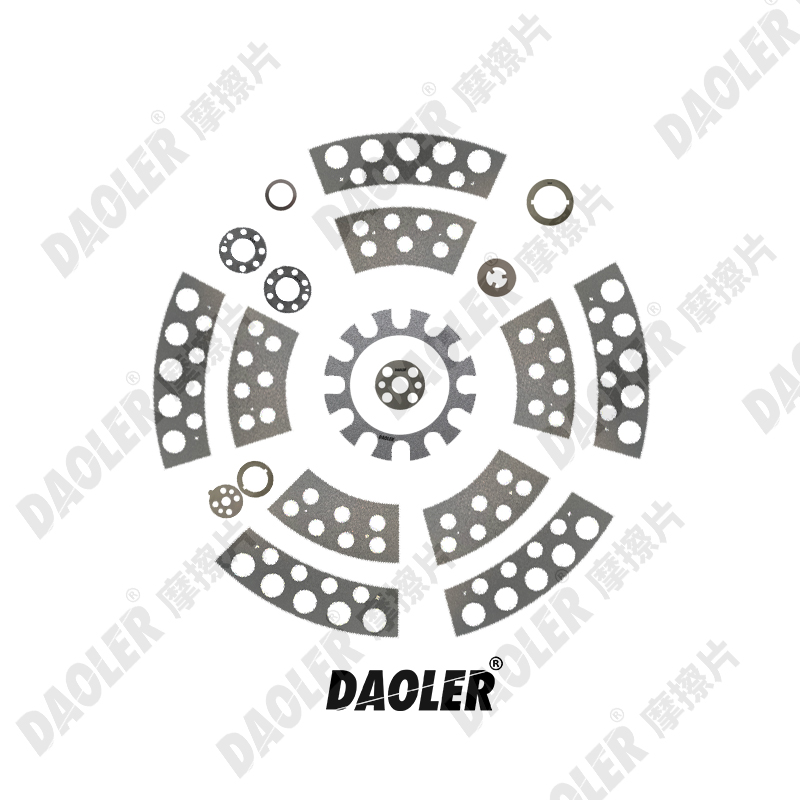

The robotic joint module is a highly precise integrated power transmission unit, comprising a servo motor, a harmonic drive, bearings, an encoder, and structural members. Its critical fastener connections face four major challenges:

| Challenge | Consequence | Solution by DAOLER® Diamond Friction Washers |

|---|---|---|

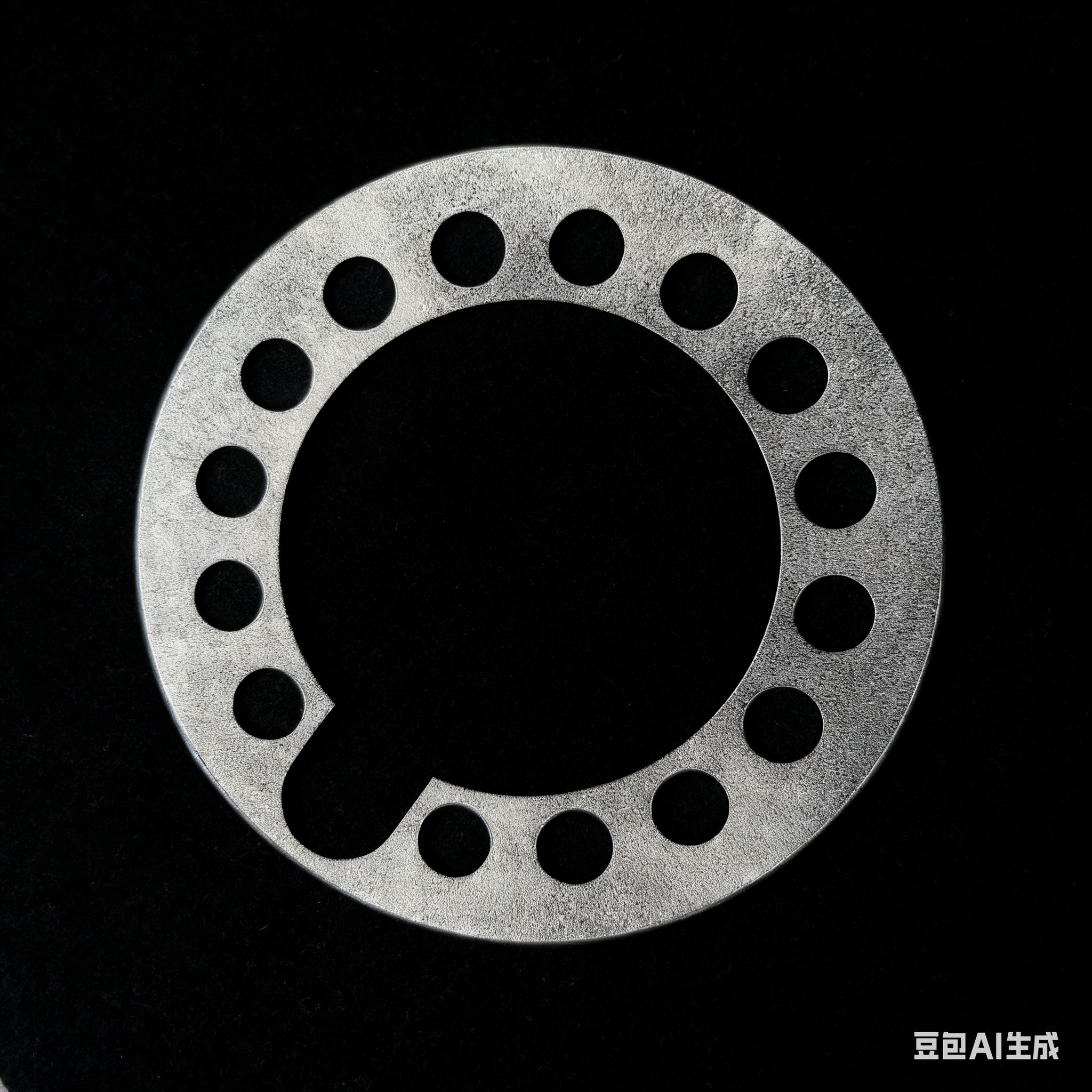

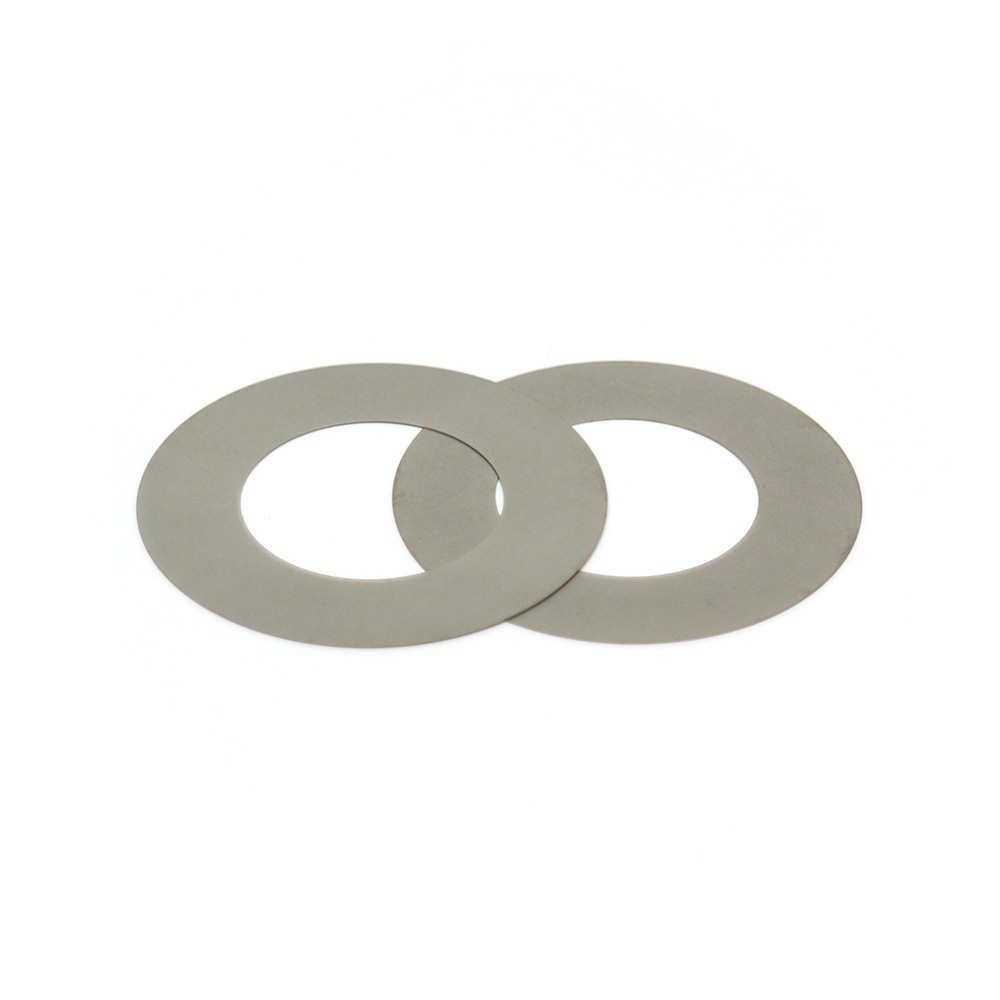

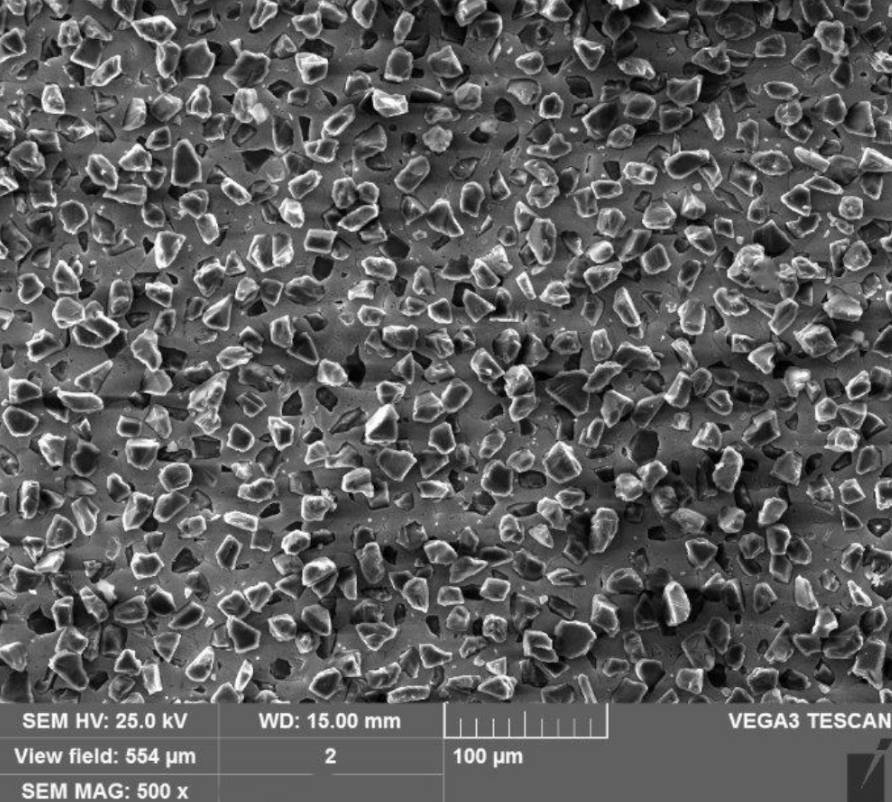

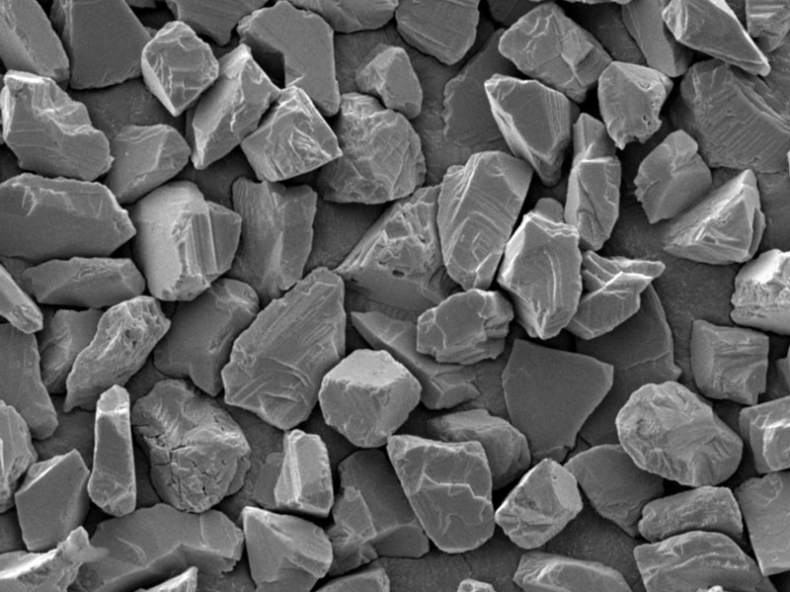

| 1. Micro-Slip Under High Alternating Torque | Leads to positioning drift, induces backlash, accelerates wear, and ultimately causes loss of precision. | Diamond Particle Mechanical Interlock: The ultra-hard diamond particles embedded in the surface generate an extremely high static friction coefficient, creating a pure mechanical bite that completely eliminates relative sliding at the microscopic level. |

| 2. Bolt Preload Relaxation Under Long-Term Vibration | Connection stiffness degrades over time, dynamic response characteristics change, causing noise and loosening risks. | Superior Anti-Loosening Performance: Its locking principle does not rely on elastic deformation but on the stable bite formed between the diamonds and the contact surface. Its resistance to vibration-induced loosening far exceeds traditional solutions, ensuring lifelong preload stability. |

| 3. Corrosion and Wear in Harsh Environments | Internals can corrode due to lubricants, condensation, or environmental contaminants, affecting lifespan and performance. | Nickel-Plated Steel Substrate + Corrosion Resistance: The substrate provides excellent rust protection, while the exceptional wear resistance of diamonds ensures long-term stability of the frictional properties without degradation from surface wear. |

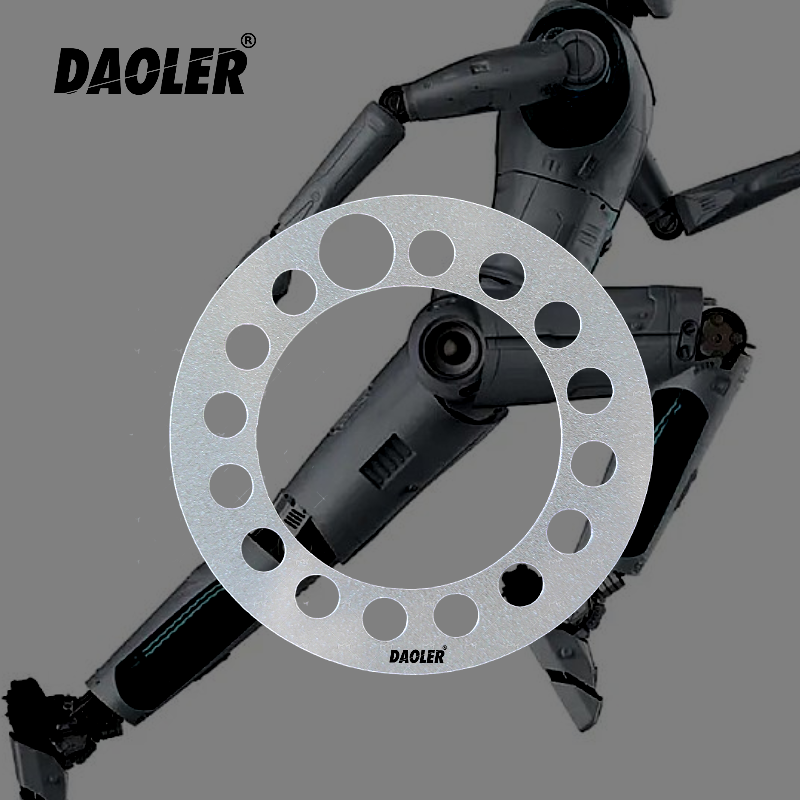

| 4. Need for Lightweight & Low-Profile Design in Compact Spaces | Traditional thick washers or complex locking mechanisms increase axial dimensions and weight, limiting joint design. | Low-Profile Design: While delivering ultimate performance, the washers themselves are extremely thin and light, freeing up valuable space for more compact and lightweight joint design. |

Part 2: Specific Applications and Value in Key Subsystems

1. Connection Between Harmonic Drive and Output Flange

The harmonic drive is the essence of the joint. The connection between its output flange and the arm link must be absolutely rigid. Any micro-slip is directly amplified into millimeter-level errors at the end-effector. Applying DAOLER® washers here ensures zero-backlash torque transmission from the reducer to the arm, translating the reducer's theoretical precision into the robot's actual precision.

2. Axial Preload and Fixing of Bearings

Robotic joint bearings, particularly crossed roller bearings, require precise axial preload to eliminate play and ensure smooth motion. Using DAOLER® washers to secure bearing housings prevents preload loss due to vibration, maintaining the bearing's optimal operating condition and joint rotational accuracy over the long term.

3. Connection Between Motor Rotor and Reducer Input Shaft

In high dynamic response scenarios, the spline or key connection between the motor rotor and the reducer input shaft requires extremely high anti-loosening security. DAOLER® washers effectively lock this critical interface, ensuring instantaneous, lossless torque transmission during high-frequency forward/reverse rotation.

4. Flange Connections of Structural Housings

The stiffness of flange connections between the joint housing and support members directly impacts the joint's natural frequency and shock resistance. Implementing the DAOLER® solution significantly increases connection stiffness, thereby enhancing the machine's overall vibration damping capability and dynamic performance.

Part 3: Transformative Value for Robotic Design

Doubled Precision Lifespan: Fundamentally suppresses accuracy degradation caused by connection loosening, enabling robots to maintain factory precision over a longer lifecycle and reducing total cost of ownership.

Enhanced Dynamic Performance: Higher connection stiffness and stability allow joints to utilize more aggressive servo control parameters, achieving faster response speeds and higher bandwidth, improving cycle times.

Enables Compact Design: Replaces complex multi-lock structures, allowing for the design of thinner, more compact joint modules, leading to better arm design and power density for collaborative robots.

Increased Reliability: Provides maintenance-free, permanent locking security under harsh conditions of high speed, high load, and 7x24 continuous operation, significantly improving Mean Time Between Failures (MTBF).

Part 4: Collaboration Model: From Standard Products to Deep Co-Development Customization

We understand that leading robotics manufacturers have the most demanding, personalized requirements for components. DAOLER® not only offers proven standard products but also possesses strong engineering customization capabilities:

Dimensional Customization: Adapts to various non-standard bolt sizes and flange geometries.

Friction Coefficient Customization: Can tailor the washers to provide a specific range of friction coefficients based on joint design preload requirements.

Special Environment Adaptation: Develops specialized versions for use in vacuum, high/low temperature, or specific lubricant media environments.

We sincerely invite robotics manufacturers and joint module developers to apply for samples for testing and validation. Experience firsthand how DAOLER® Diamond Friction Washers can inject a more powerful "rigid core" into your next-generation robotic products.

On the path to pursuing ultimate robotic performance, every micron of improvement is crucial. DAOLER® is committed to being your most reliable partner, locking in every bit of precision and supporting every innovation with diamond-like steadfastness.

请先 登录后发表评论 ~