当扭矩成为挑战:新一代智能紧固方案如何提升重型设备可靠性

在重型机械、风电设备和大型工程结构中,多螺栓高强度紧固是确保结构安全的基础。传统方案依赖极高的预紧力防止滑动,但长期运行中,这种“硬对抗”模式会带来一系列问题:

传统高扭矩紧固的隐患

螺栓疲劳与断裂:周期性载荷和振动导致应力集中,螺栓逐渐产生微裂纹

维修成本攀升:故障往往需要大规模拆卸,更换成本高昂

非计划停机损失:关键设备意外停机可能引发生产线停滞,经济损失巨大

过度设计负担:为应对潜在滑动,结构常被过度加强,增加重量与材料成本

行业变革中的新需求

随着设备紧凑化、轻量化与电气化转型,传统方案面临新挑战:

更紧凑的设计需要更高的扭矩密度

轻量化材料(如高强度铝合金、复合材料)对连接提出新要求

电机驱动的瞬时高扭矩输出需要更可靠的防松解决方案

生命周期成本控制成为关键考量

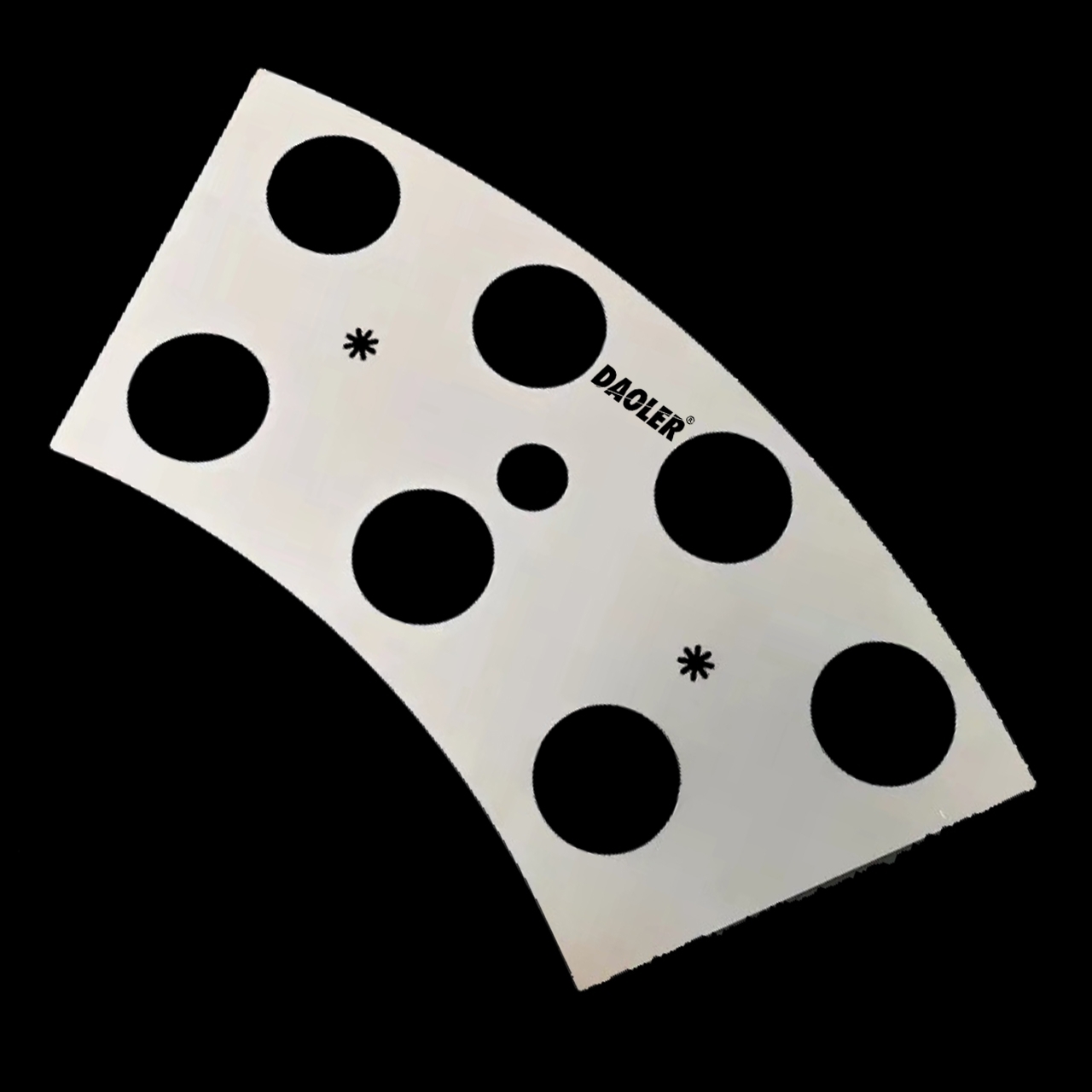

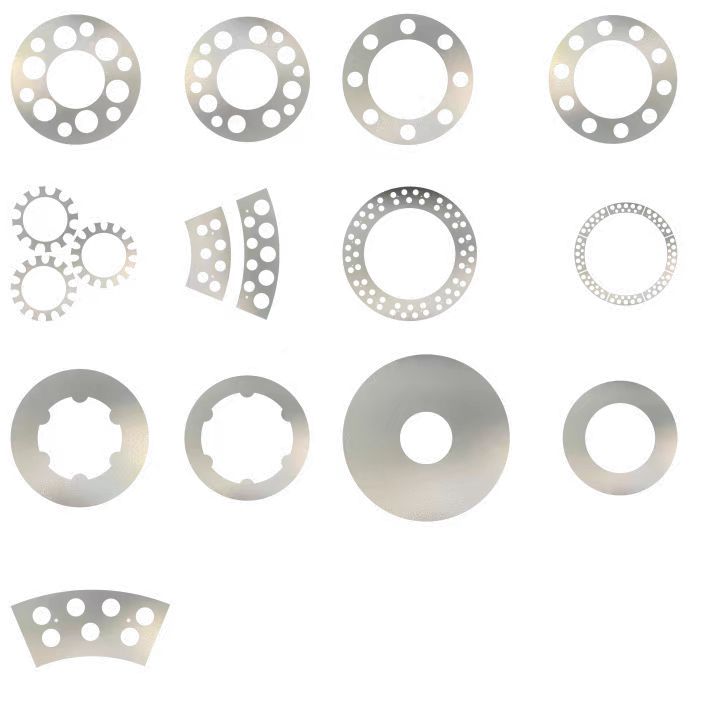

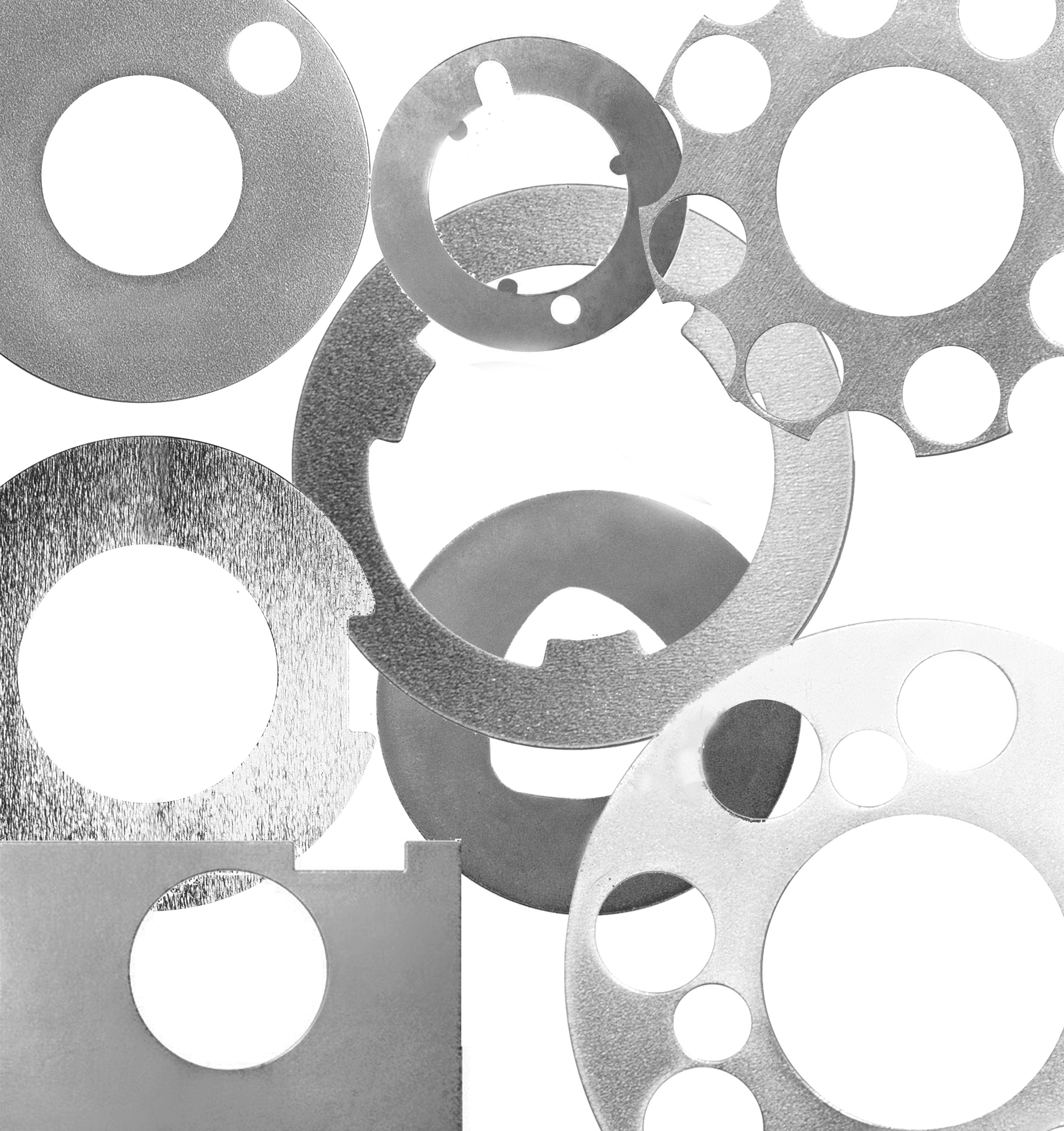

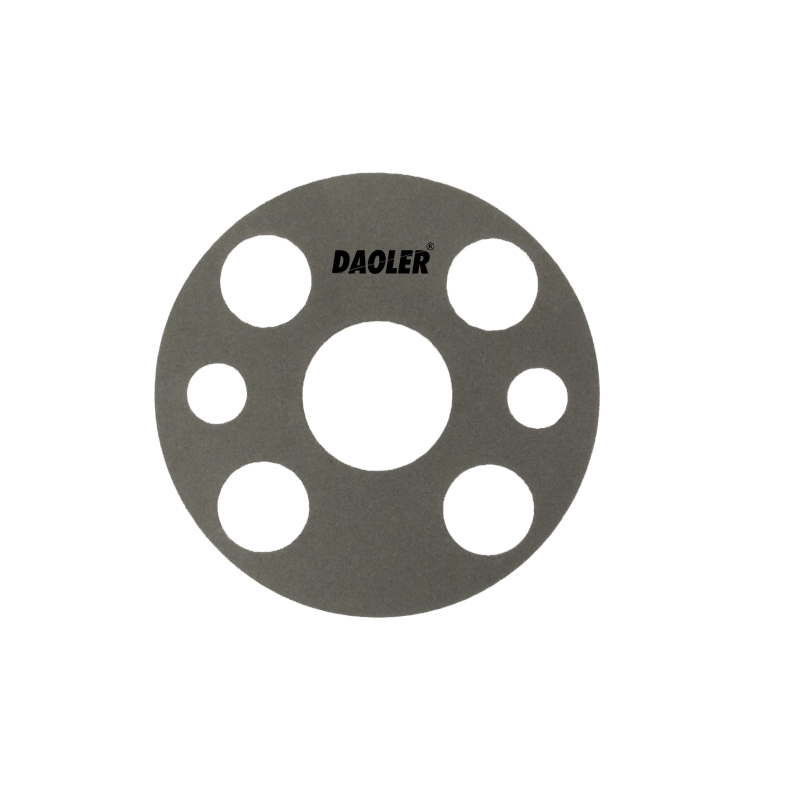

创新解决方案:高性能摩擦垫片技术

DAOLER摩擦垫片通过材料与结构创新,系统性解决上述问题:

核心技术优势

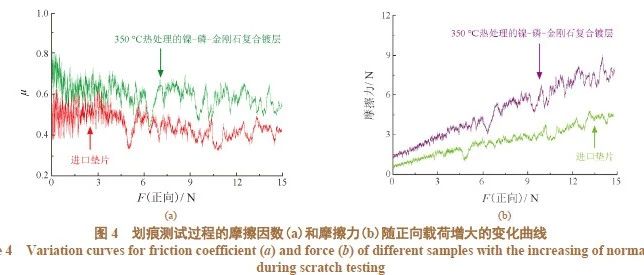

摩擦系数提升可达4倍

特殊表面处理与微结构设计大幅增加界面摩擦

可在相同预紧力下提供更高抗滑移能力

或同等抗滑移要求下降低螺栓载荷30%-50%

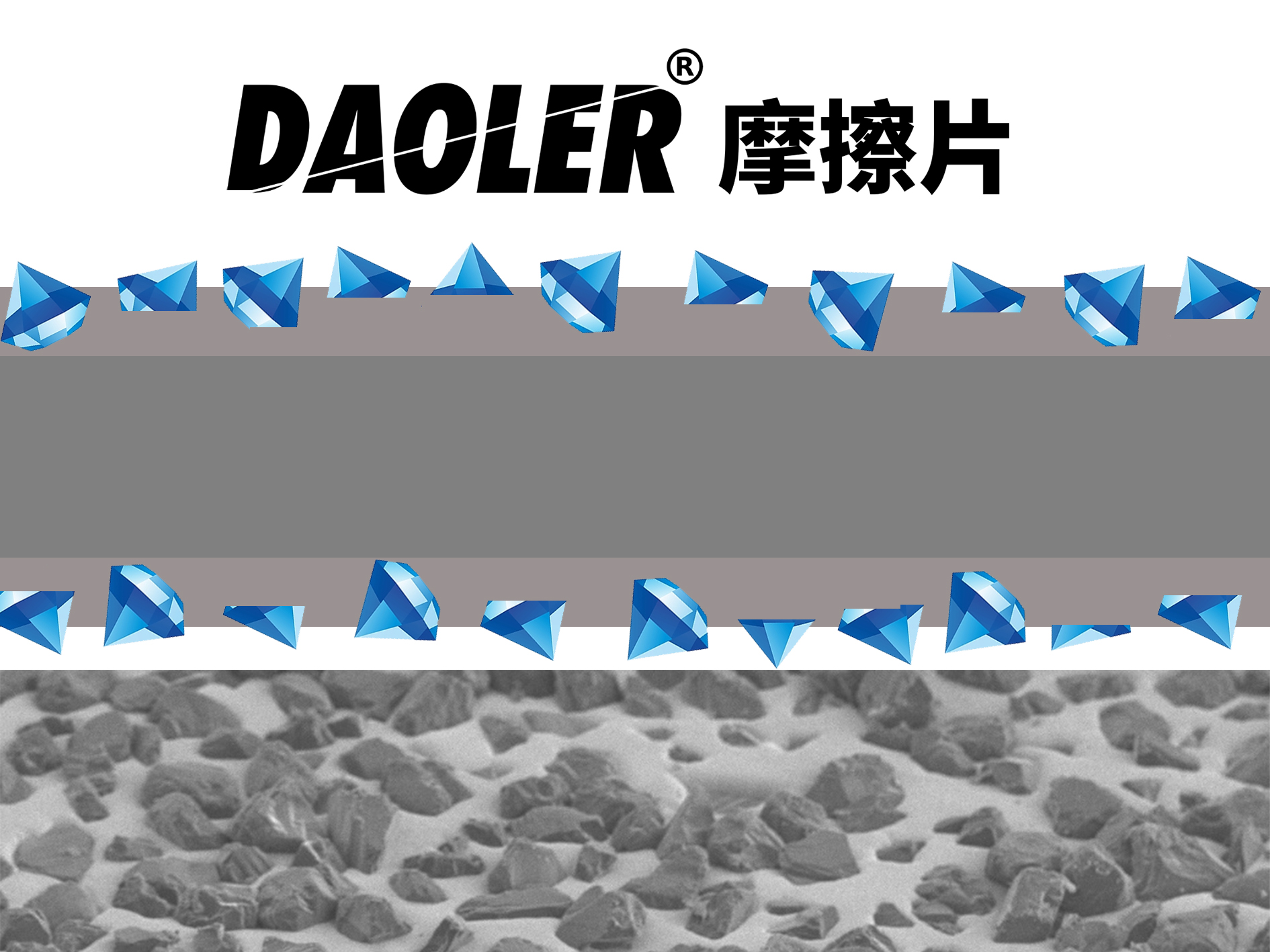

超高表面硬度(1000 HV)

耐磨性极佳,长期使用性能稳定

嵌入保护基材,避免对连接件造成损伤

耐受腐蚀环境,保持长期有效性

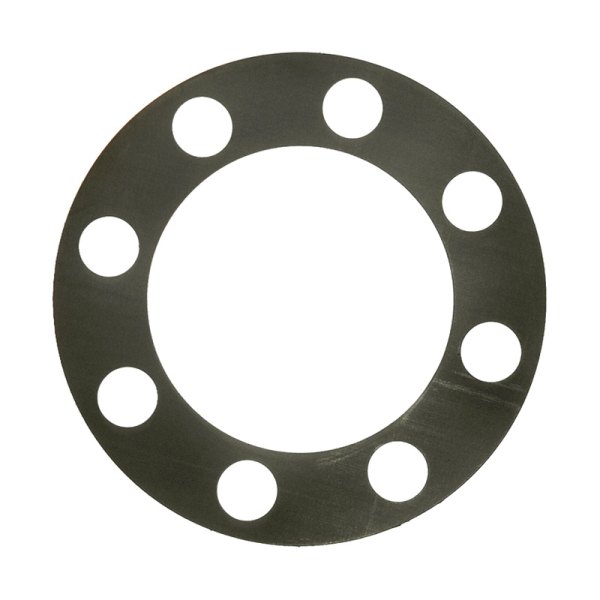

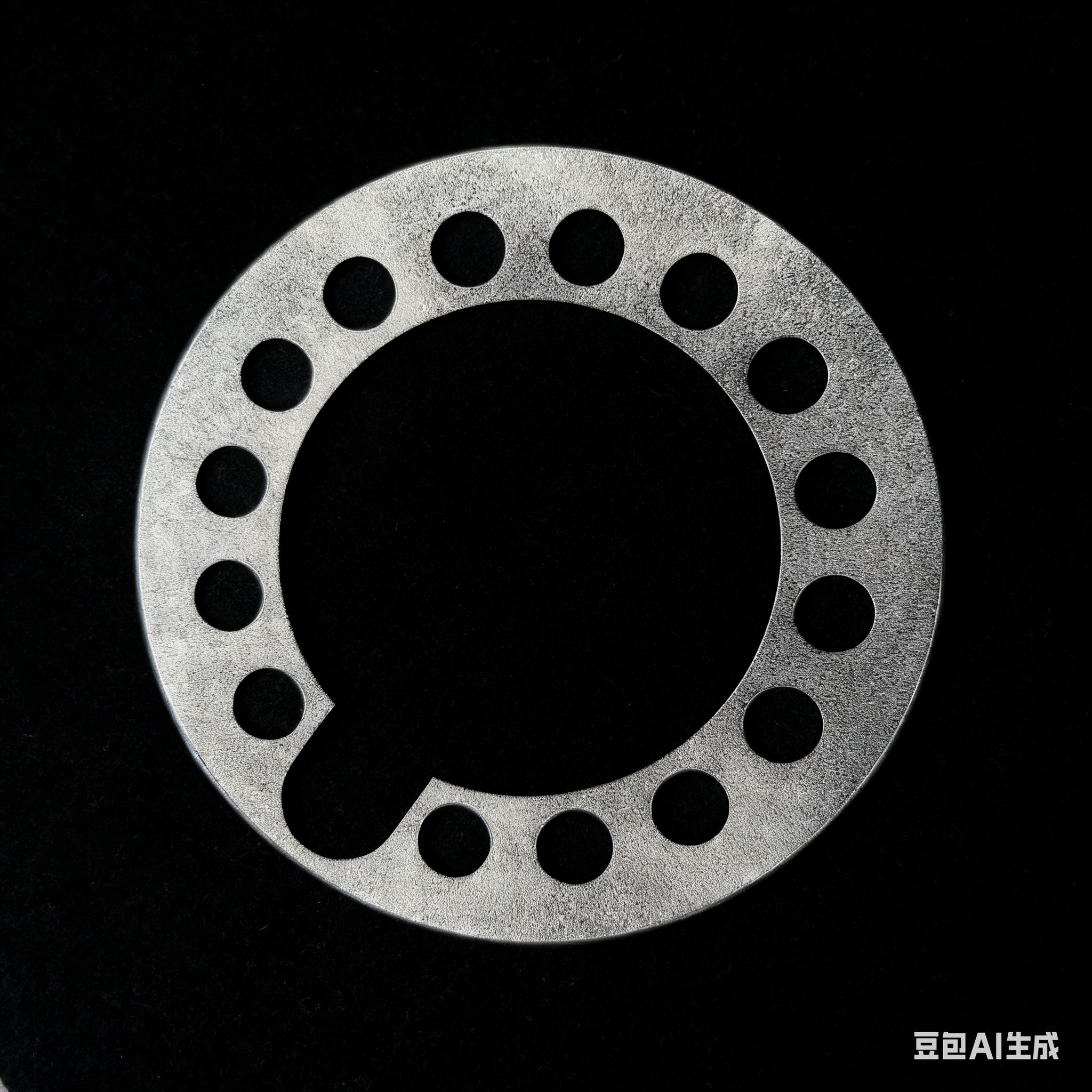

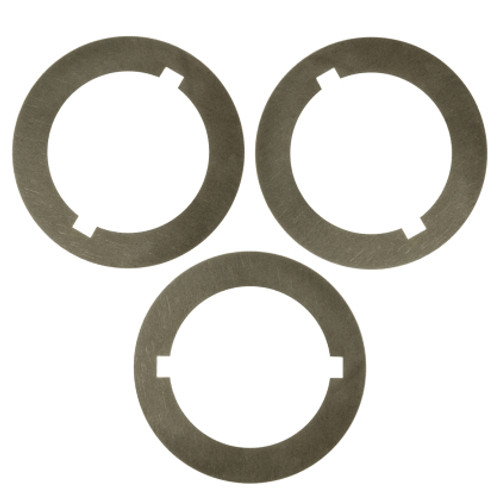

轻量化集成设计

超薄设计几乎不增加连接系统重量

与现有螺栓规格完全兼容,无需修改结构

适用于对重量敏感的航空航天、新能源汽车等领域

卓越的抗振动性能

通过动态摩擦学优化,显著降低振动松动风险

实验室测试显示,振动环境下紧固保持时间延长5-8倍

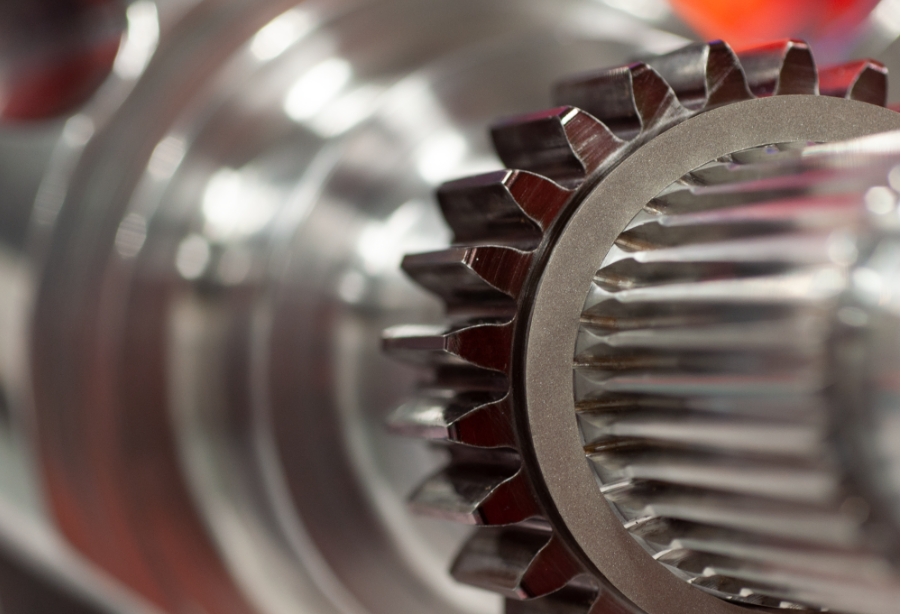

特别适用于发动机、传动系统等高振动场景

应用效益分析

延长螺栓寿命:降低应力幅值,延缓疲劳裂纹萌生

减少维护需求:预计可将螺栓相关维护减少60%以上

提升安全余量:在极端载荷下保持连接完整性

降低总成本:虽然初始投资增加,但全生命周期成本显著下降

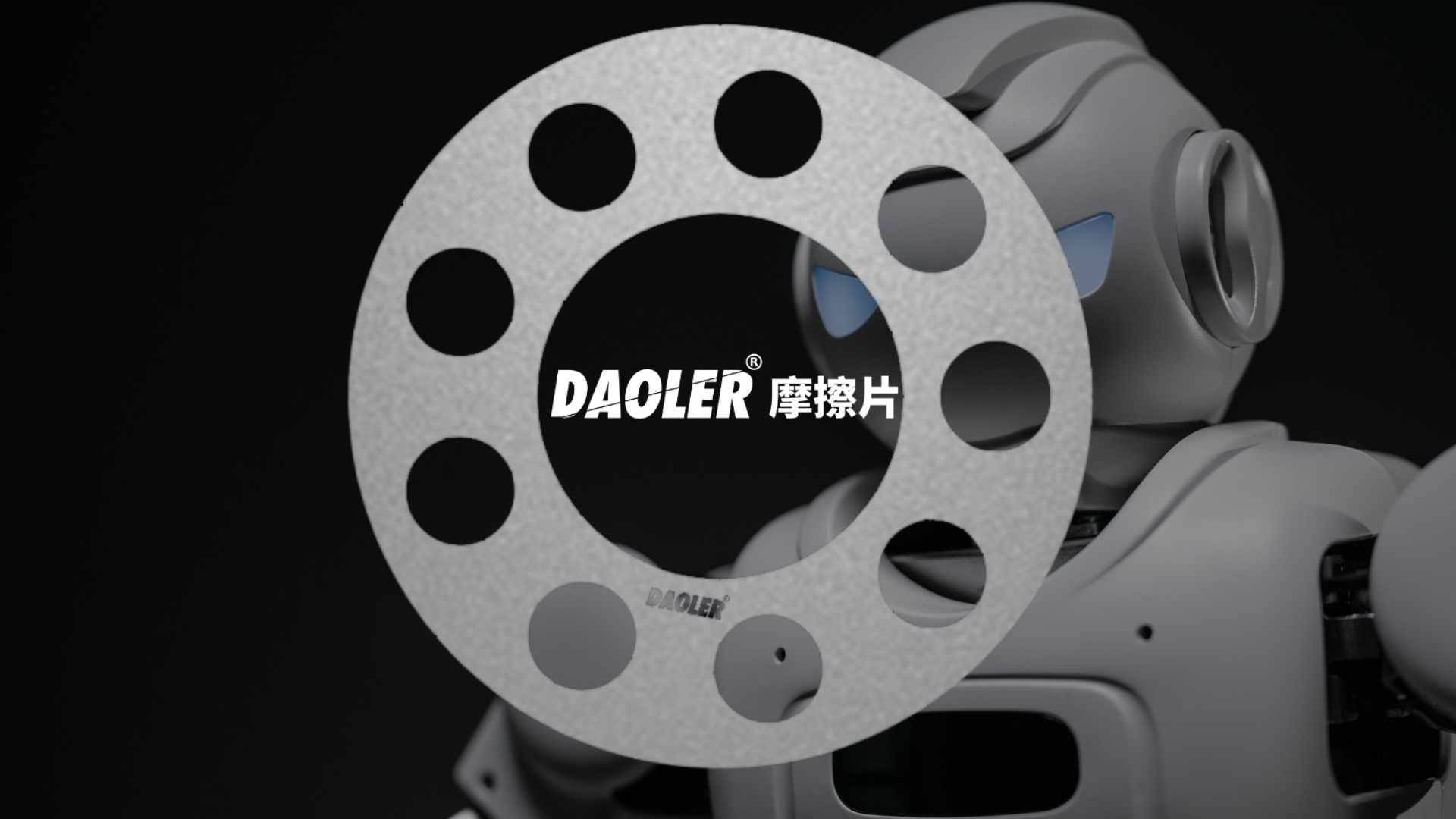

行业应用场景

风电塔筒法兰连接

工程机械重载关节

轨道交通转向架

矿山设备关键连接

航空航天结构件

在设备高性能化与电气化趋势不可逆转的今天,单纯依赖增加螺栓规格和预紧力的时代已经过去。DAOLER摩擦垫片代表了一种更智能的解决方案:通过界面摩擦管理而非螺栓本身承受全部载荷,实现了紧固系统的“软升级”。这不仅解决了当下的扭矩挑战,更为下一代紧凑型高功率密度设备提供了可靠的连接基础。

技术创新正在重新定义机械连接的可靠性标准——从“更大力气”转向“更加聪明”,这或许正是工业进步的一个微小但深刻的缩影。

In heavy machinery, wind power equipment, and large engineering structures, multi-bolt high-strength fastening is the foundation of structural safety. Traditional solutions rely on extremely high preload forces to prevent slippage, but over long-term operation, this "hard confrontation" approach leads to a series of issues:

Hidden Dangers of Traditional High-Torque Fastening

Bolt Fatigue and Fracture: Cyclic loads and vibration cause stress concentration, leading to gradual micro-cracks in bolts.

Rising Maintenance Costs: Failures often require extensive disassembly, resulting in high replacement costs.

Losses from Unplanned Downtime: Unexpected downtime of critical equipment can halt production lines, causing significant economic losses.

Burden of Over-Engineering: Structures are often overbuilt to prevent potential slippage, increasing weight and material costs.

New Demands in Industry Transformation

As equipment becomes more compact, lightweight, and electrified, traditional solutions face new challenges:

More compact designs require higher torque density.

Lightweight materials (such as high-strength aluminum alloys, composites) impose new demands on connections.

The instantaneous high torque output of electric motors requires more reliable anti-loosening solutions.

Lifecycle cost control has become a key consideration.

Innovative Solution: High-Performance Friction Shim Technology

DAOLER friction shims address these issues systematically through material and structural innovation:

Core Technical Advantages

Friction Coefficient Increase of Up to 4 Times

Special surface treatments and microstructure design significantly increase interface friction.

Provides higher anti-slip capability under the same preload force.

Alternatively, reduces bolt load by 30%-50% while meeting the same anti-slip requirements.

Ultra-High Surface Hardness (1000 HV)

Excellent wear resistance ensures stable long-term performance.

Embeds and protects base materials, avoiding damage to connected parts.

Resists corrosive environments, maintaining long-term effectiveness.

Lightweight Integrated Design

Ultra-thin design adds almost no weight to the connection system.

Fully compatible with existing bolt specifications, requiring no structural modifications.

Suitable for weight-sensitive fields such as aerospace and new energy vehicles.

Exceptional Vibration Resistance

Dynamically optimized tribology significantly reduces the risk of vibration-induced loosening.

Laboratory tests show fastener retention time extended by 5-8 times in vibrating environments.

Particularly suitable for high-vibration scenarios such as engines and transmission systems.

Application Benefit Analysis

Extended Bolt Service Life: Reduces stress amplitude, delaying the initiation of fatigue cracks.

Reduced Maintenance Needs: Expected to decrease bolt-related maintenance by over 60%.

Increased Safety Margin: Maintains connection integrity under extreme loads.

Lower Total Cost of Ownership: Although initial investment may increase, the total lifecycle cost is significantly reduced.

Industry Application Scenarios

Wind turbine tower flange connections

Heavy-duty joints in construction machinery

Railway bogie frames

Critical connections in mining equipment

Aerospace structural components

(DAOLER®摩擦垫片版权所有,侵权必究)

请先 登录后发表评论 ~