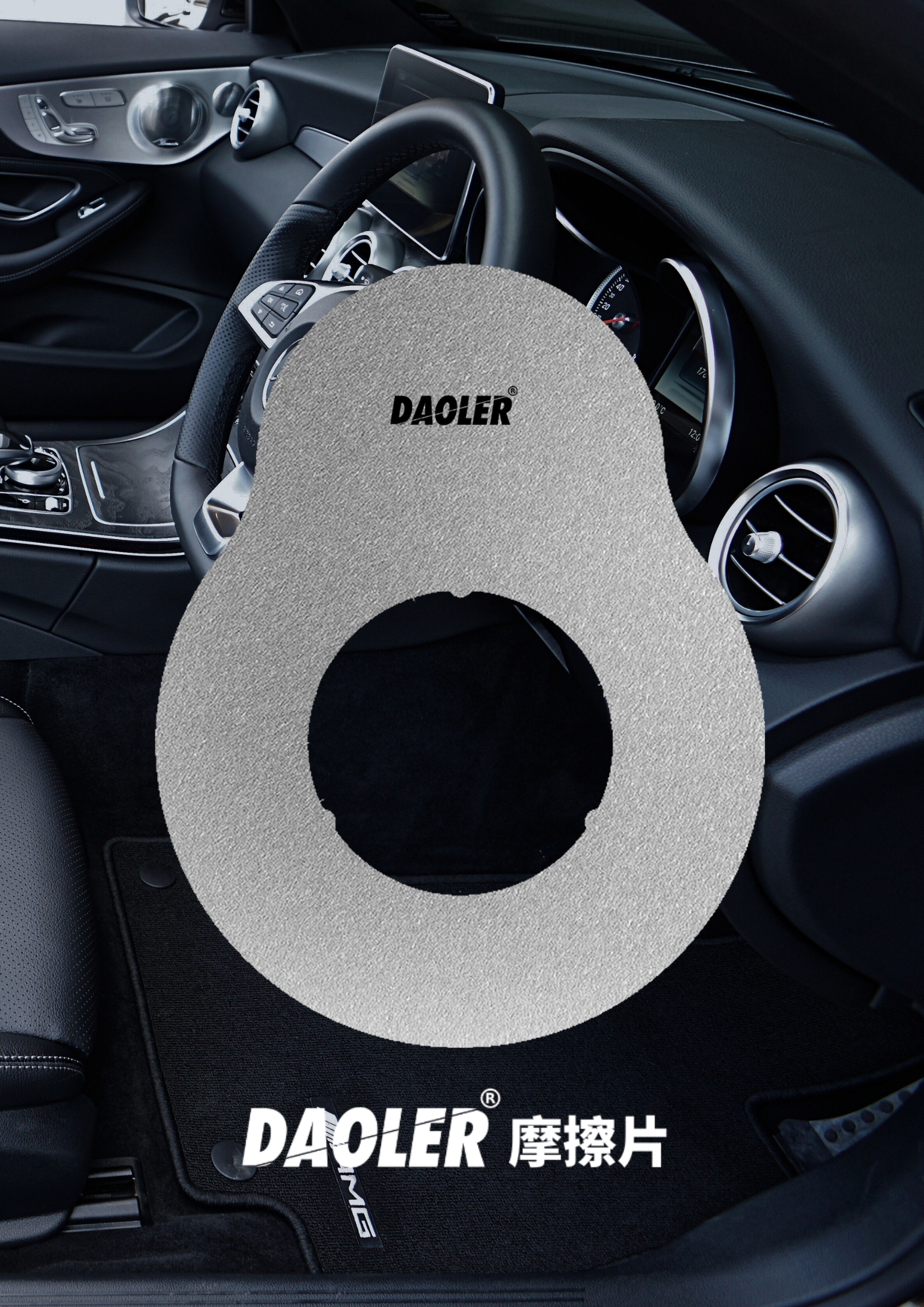

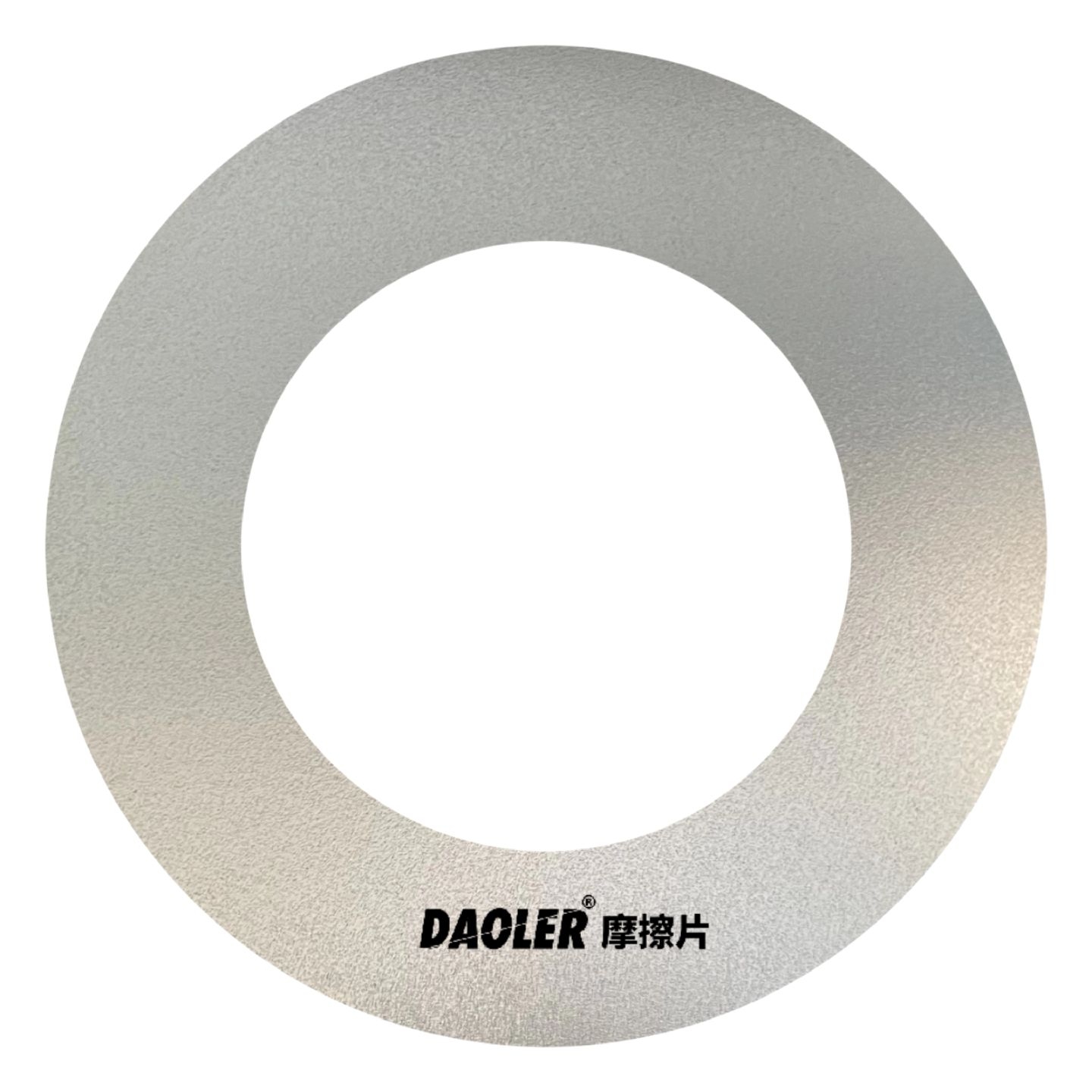

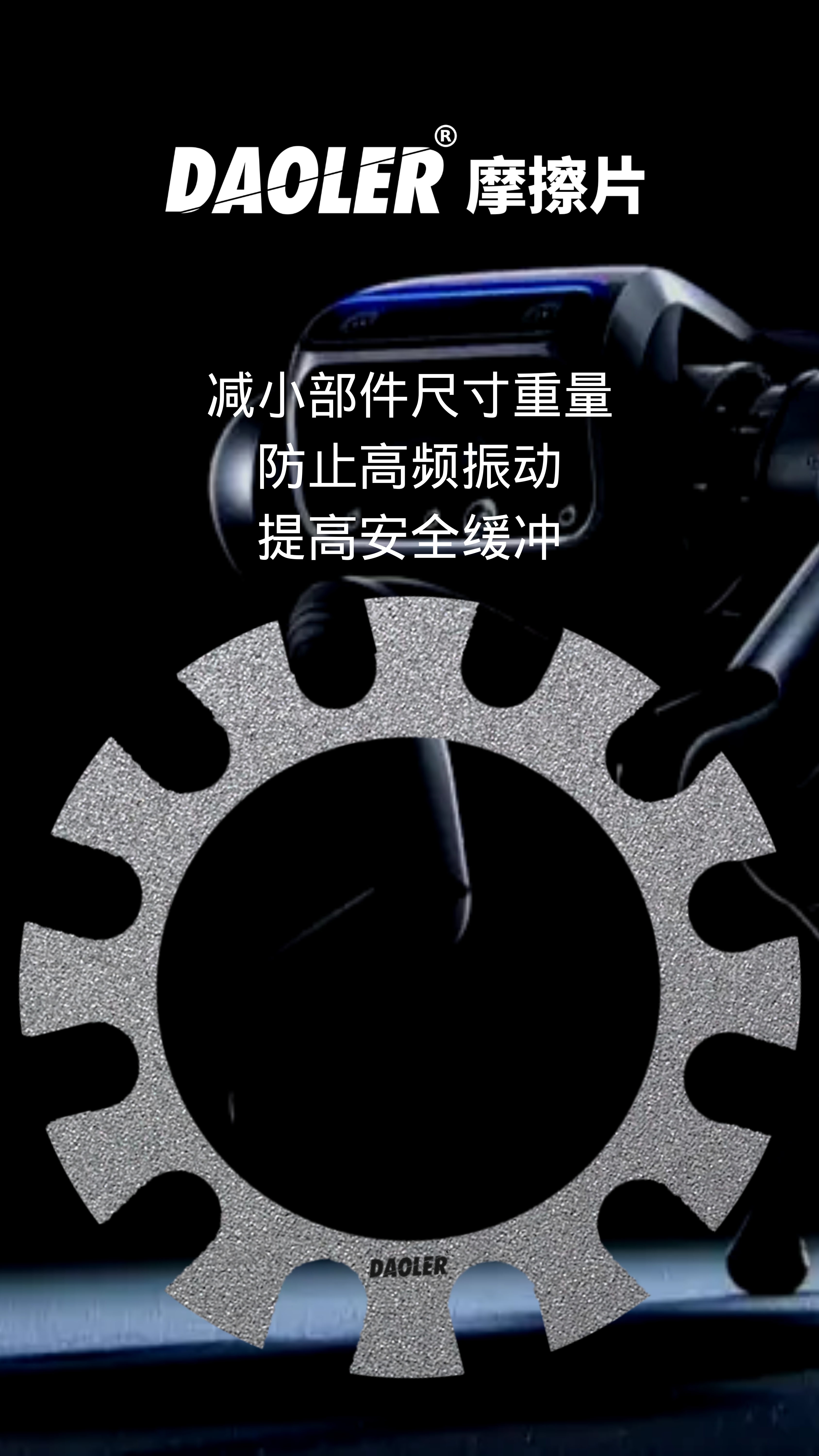

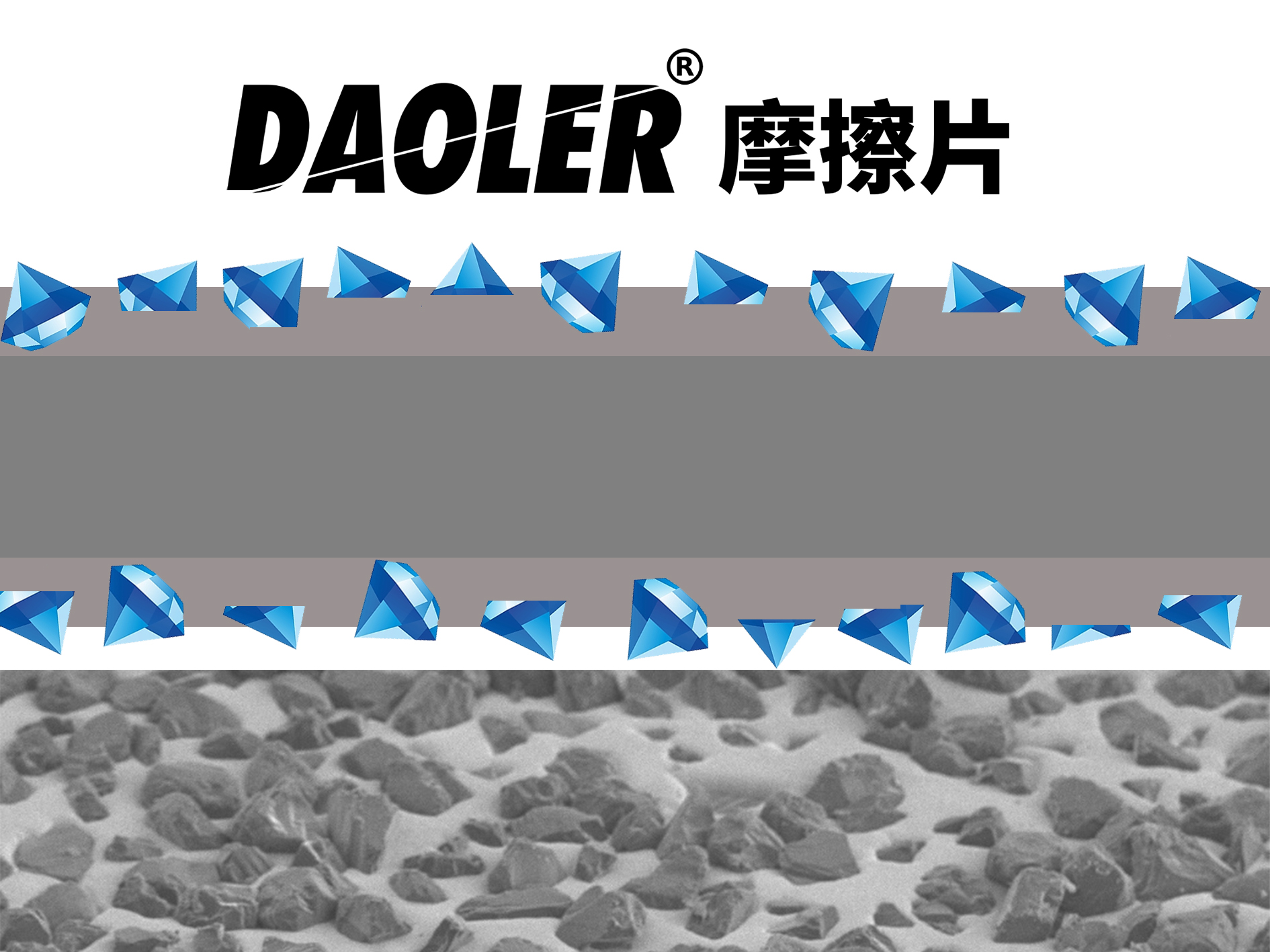

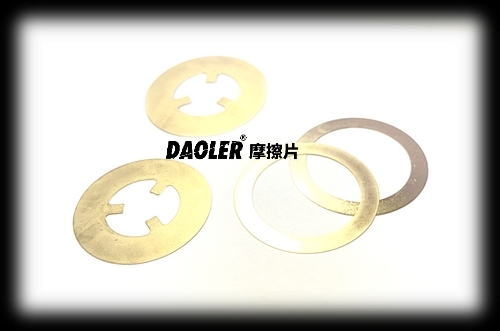

金刚石摩擦垫圈在新能源汽车行业应用

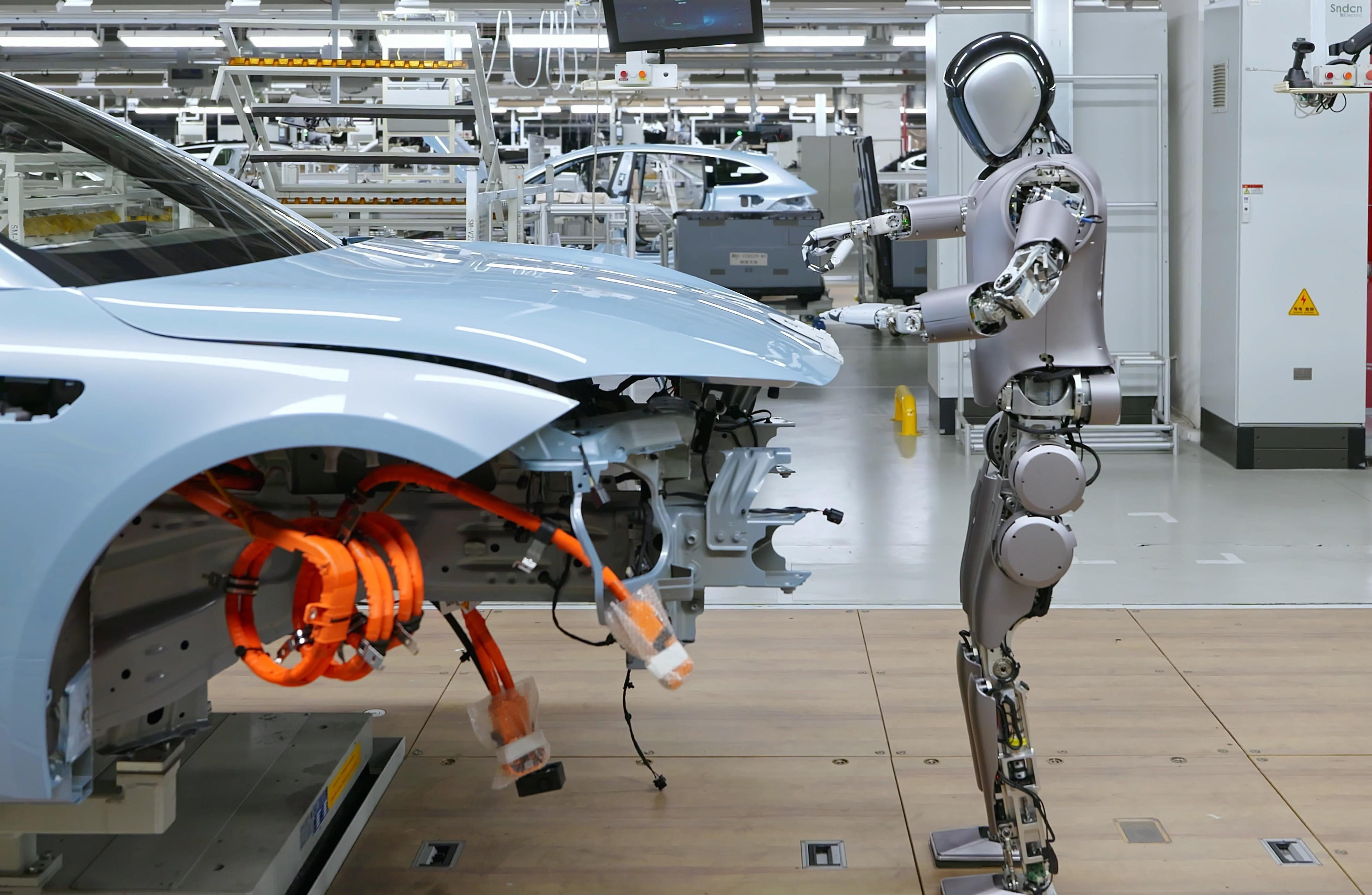

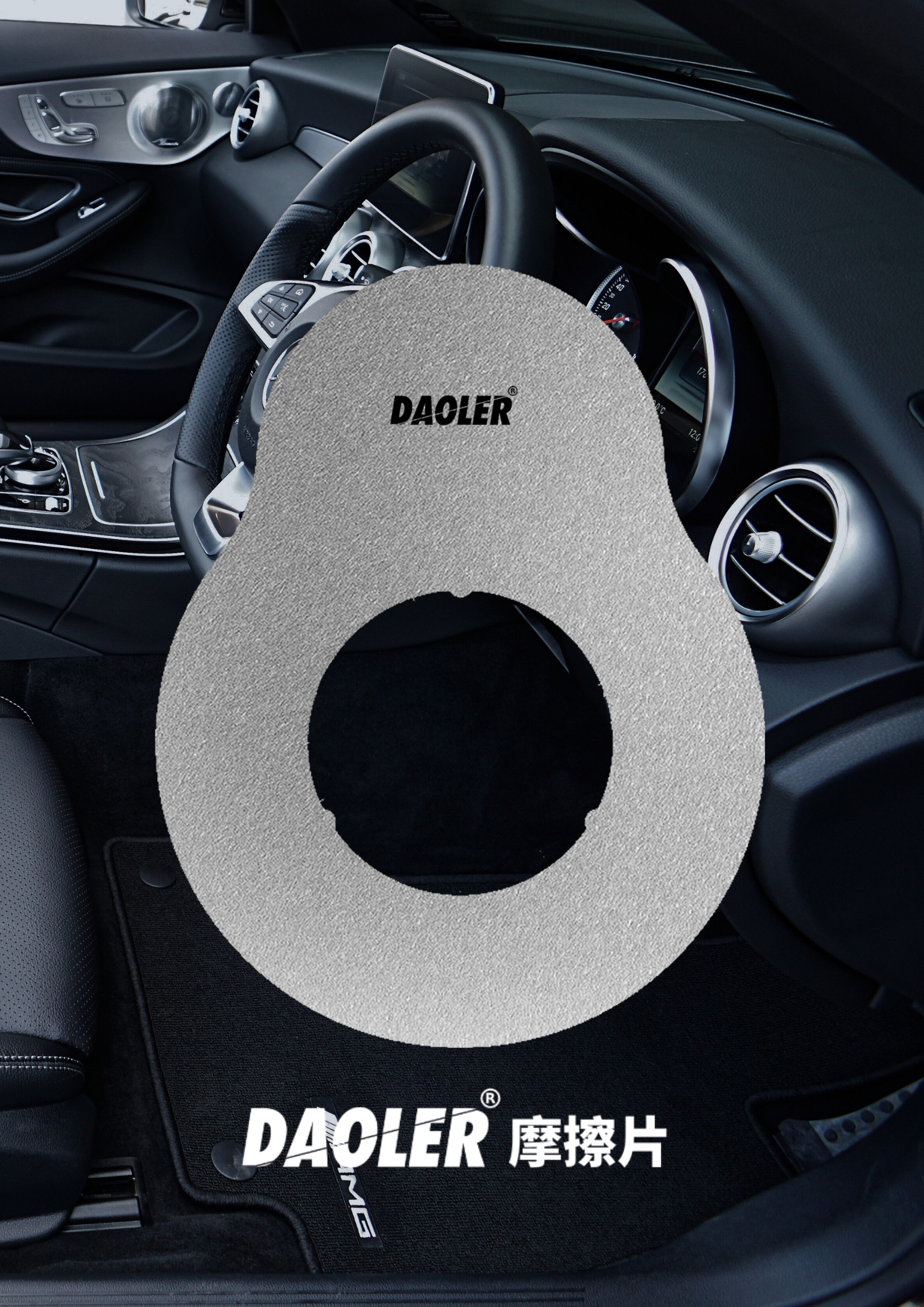

新能源汽车使用钻石摩擦垫片是一个相对新颖的技术应用,这种垫片可能利用钻石(或金刚石)的优异物理和化学性质来提供卓越的摩擦性能和耐久性。以下是一些关于新能源汽车用钻石摩擦垫片的可能特性和优势:

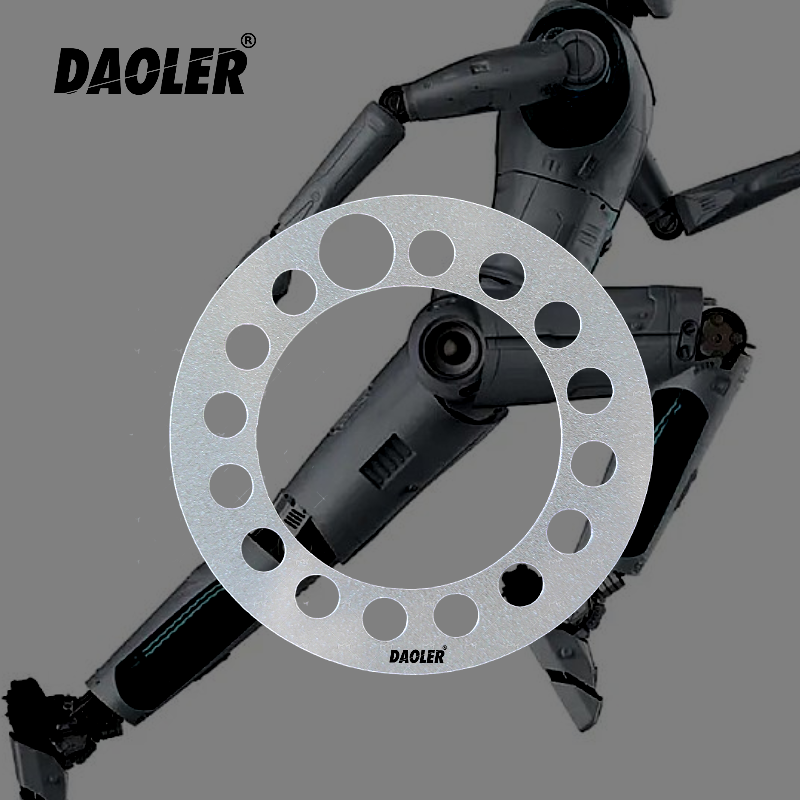

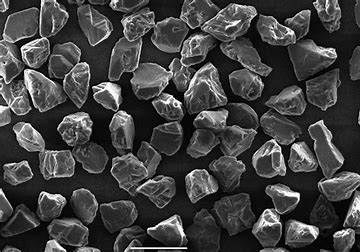

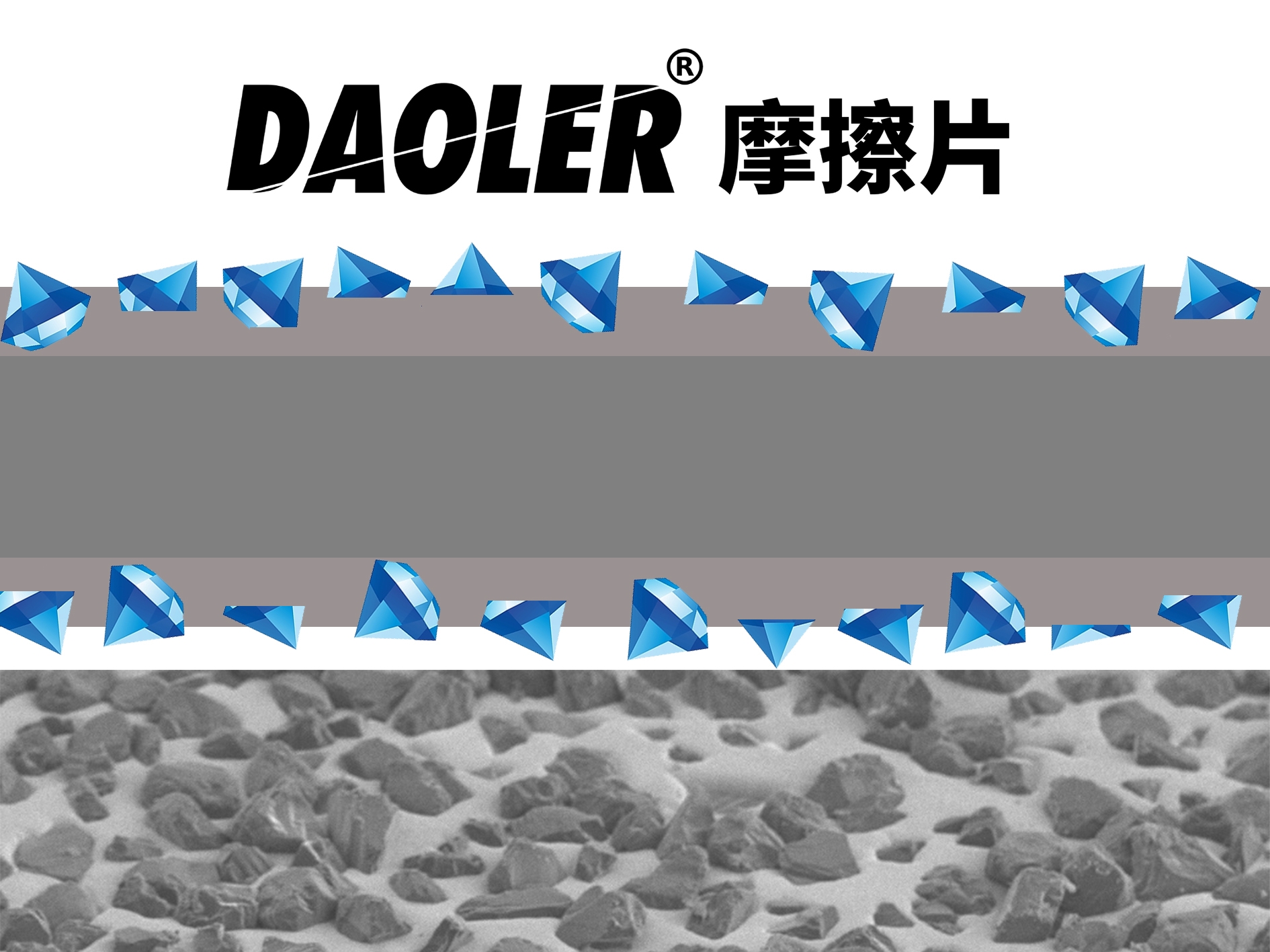

- 高硬度和耐磨性:钻石是自然界中最硬的物质,因此钻石摩擦垫片具有极高的耐磨性,能够承受高频率和高强度的摩擦,减少磨损和更换频率。

- 优异的导热性:钻石具有优异的导热性能,这意味着它能够有效地将热量从摩擦界面传递到周围环境,减少因摩擦产生的热量对系统性能的影响。

- 化学稳定性:钻石在大多数环境中都具有极高的化学稳定性,能够抵抗氧化、腐蚀和化学反应,从而保持长期的稳定性和可靠性。

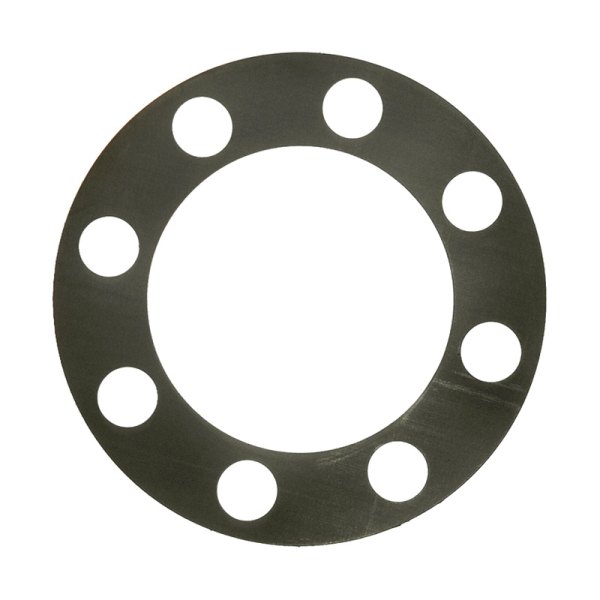

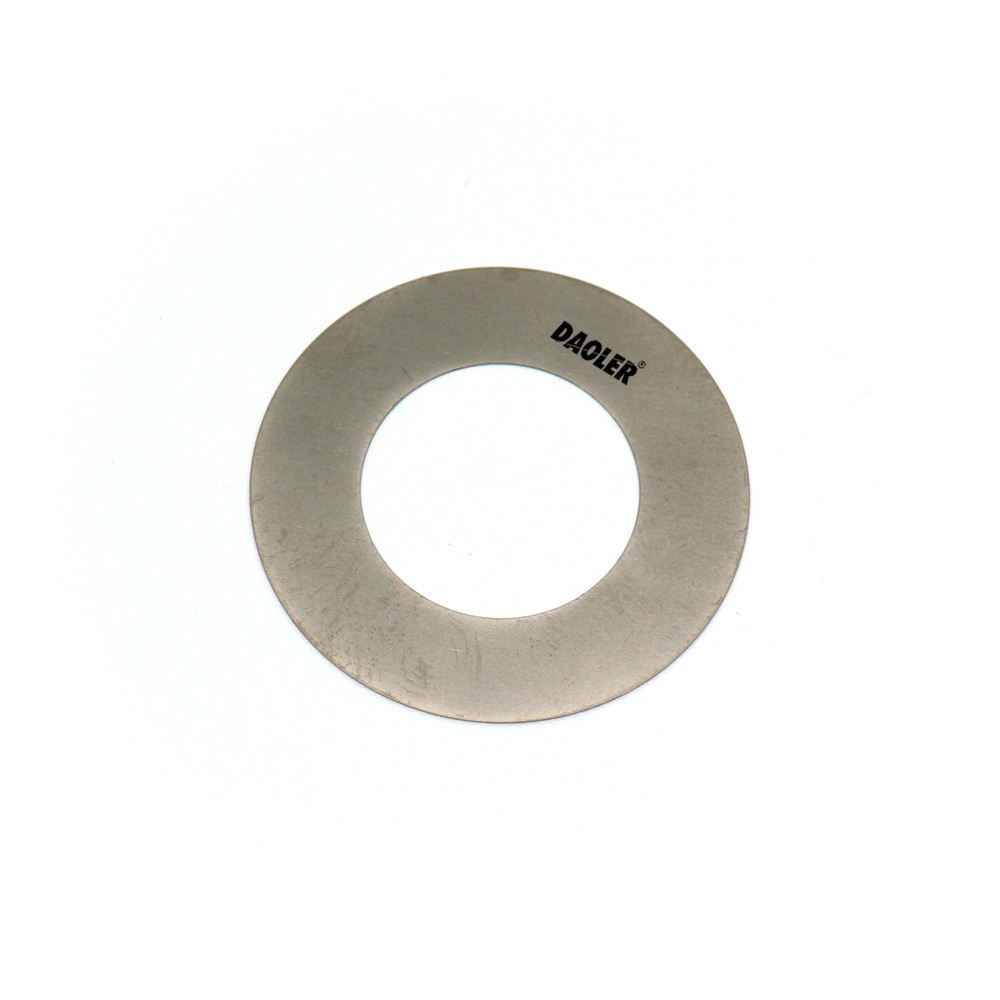

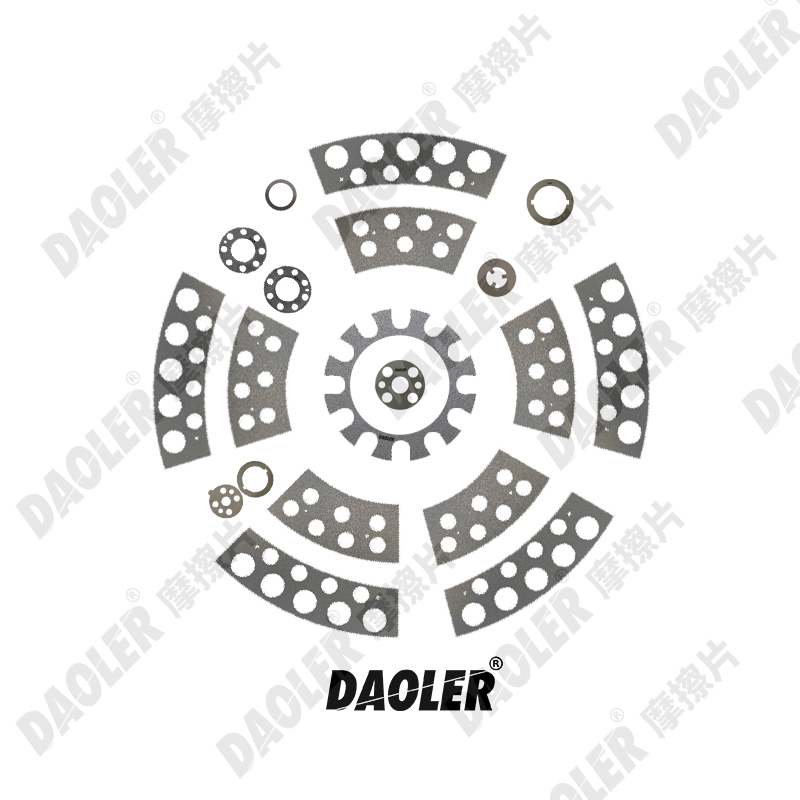

- 定制化设计:钻石摩擦垫片可以根据新能源汽车的具体需求进行定制化设计,包括尺寸、形状和表面结构等,以适应不同的摩擦条件和性能要求。

然而,需要注意的是,钻石摩擦垫片的应用也面临一些挑战和限制。首先,钻石的成本相对较高,这可能会增加新能源汽车的生产成本。其次,钻石摩擦垫片的制造过程可能相对复杂,需要高精度的加工技术和设备。最后,尽管钻石具有优异的物理和化学性能,但在某些极端条件下(如高温、高压等)可能会出现性能下降的情况。

综上所述,新能源汽车用钻石摩擦垫片具有一些潜在的优势和特性,但也需要在实际应用中考虑成本、制造难度和极端条件下的性能稳定性等因素。随着技术的不断发展和成本的逐渐降低,钻石摩擦垫片在新能源汽车领域的应用前景仍然值得期待。

The use of diamond friction washers in new energy vehicles represents a relatively novel technological application, which potentially leverages the superior physical and chemical properties of diamond (or diamond material) to provide exceptional friction performance and durability. Here are some possible characteristics and advantages of diamond friction washers for new energy vehicles:

High hardness and wear resistance: Diamond is the hardest material in nature, thus diamond friction washers possess extremely high wear resistance, able to withstand high-frequency and high-intensity friction, reducing wear and tear and the need for frequent replacements.

Excellent thermal conductivity: Diamond has excellent thermal conductivity, meaning it can effectively transfer heat from the friction interface to the surrounding environment, minimizing the impact of friction-generated heat on system performance.

Chemical stability: Diamond exhibits high chemical stability in most environments, resisting oxidation, corrosion, and chemical reactions, thereby maintaining long-term stability and reliability.

Customizable design: Diamond friction washers can be customized according to the specific needs of new energy vehicles, including size, shape, and surface structure, to adapt to different friction conditions and performance requirements.

However, it's worth noting that the application of diamond friction washers also faces some challenges and limitations. Firstly, the cost of diamond is relatively high, which may increase the production cost of new energy vehicles. Secondly, the manufacturing process of diamond friction washers can be complex, requiring high-precision processing technology and equipment. Finally, while diamond possesses excellent physical and chemical properties, its performance may degrade under certain extreme conditions, such as high temperatures and pressures.

In conclusion, diamond friction washers for new energy vehicles offer potential advantages and characteristics, but factors such as cost, manufacturing difficulty, and performance stability under extreme conditions need to be considered in practical applications. With continuous technological advancements and gradual cost reductions, the application prospects of diamond friction washers in the field of new energy vehicles remain promising.

请先 登录后发表评论 ~