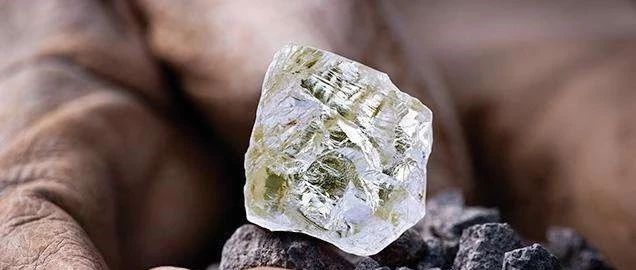

科普|揭秘金刚石:力学奇迹的奥秘

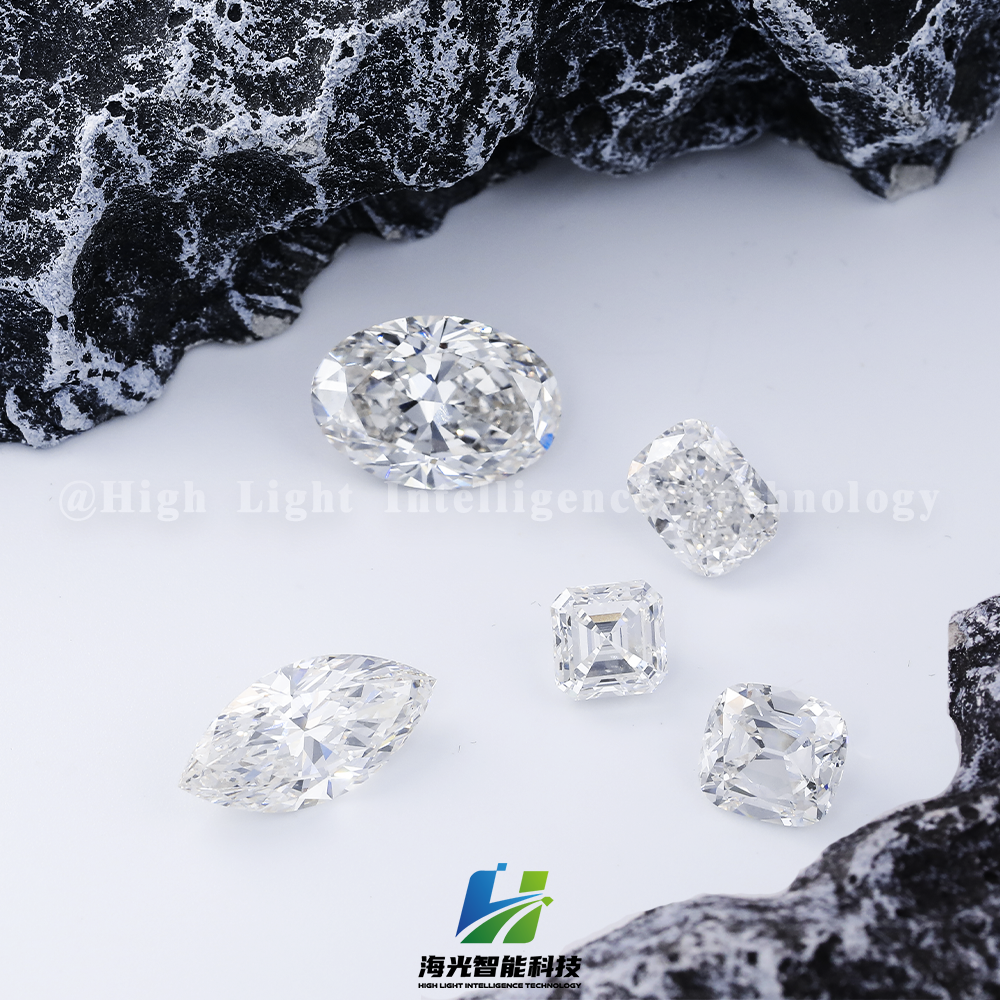

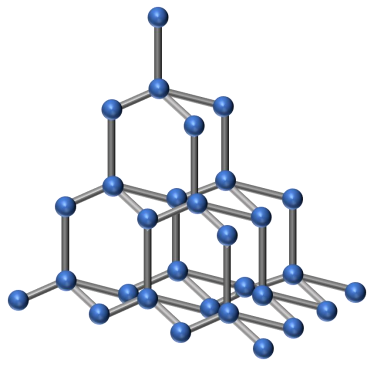

金刚石,这个自然界中天然存在的最坚硬的物质,一直以来都以其卓越的力学性能吸引着人们的目光。它的高硬度、高强度、优良的耐磨性和热膨胀系数低等特点,使得金刚石在众多领域中都有着广泛的应用。

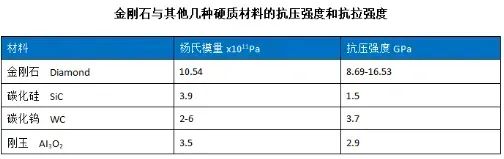

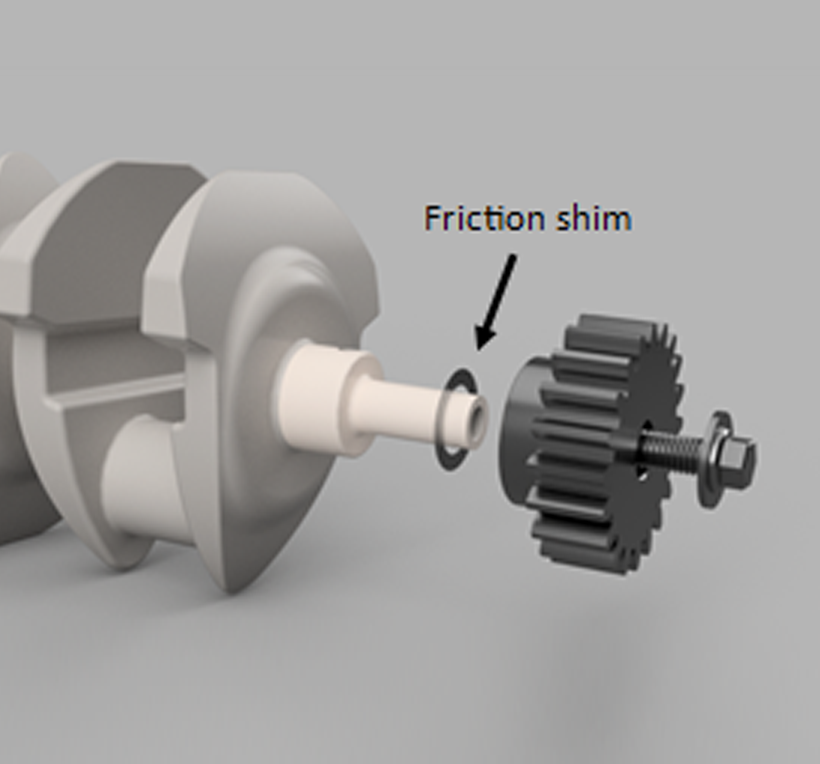

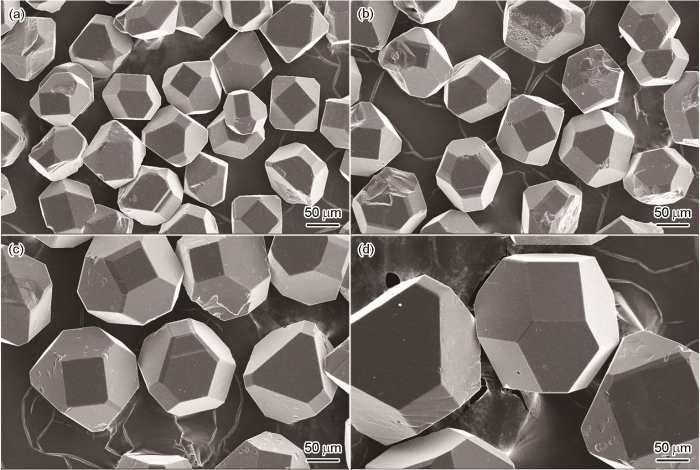

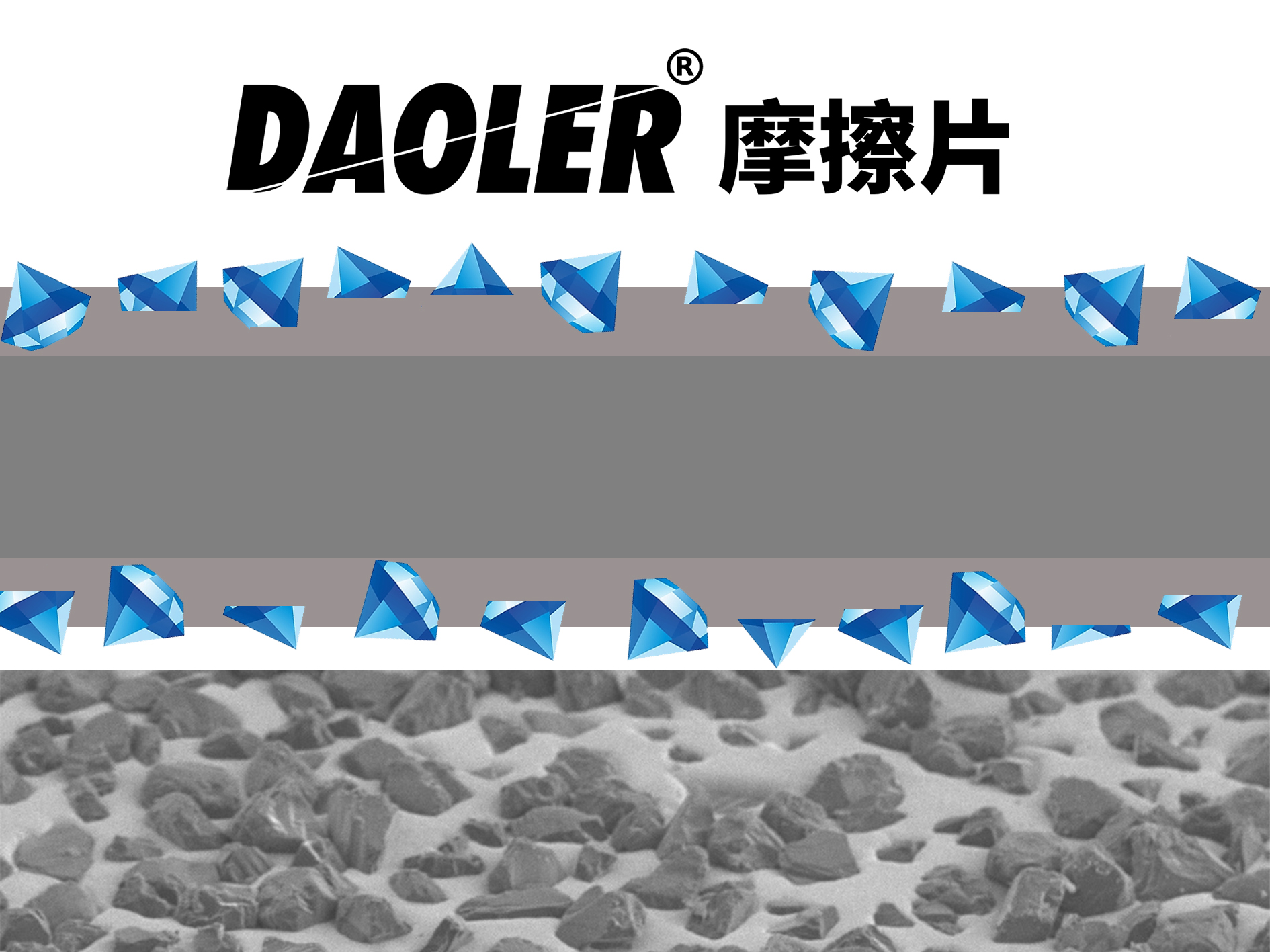

金刚石在空气中的摩擦系数为0.05-0.1,金刚石的磨耗量因摩擦方法不同而有很大变化,下表为在大致相同的条件下金刚石与各常见硬质材料摩擦后的相对磨耗量。可以看出金刚石相对于其它各种材料的磨耗量非常小,因此工业领域微米级与纳米级尺寸颗粒的金刚石微粉被大量应用于各种材料表面研磨与精细抛光。更大尺寸的合成金刚石材料烧结体还能被用在高硬钻头领域,其磨耗比范围甚至能够达到1:3×10⁴-1:8×10⁴,用作拉丝模的磨耗比的范围为1:10⁵-1:3×10⁵。

The friction coefficient of diamond in air is 0.05-0.1. The wear amount of diamond varies greatly due to different friction methods. The following table shows the relative wear amount of diamond after friction with various common hard materials under roughly the same conditions. It can be seen that the amount of wear of diamond is very small compared to various other materials. Therefore, diamond powder with micron- and nano-sized particles in the industrial field is widely used in surface grinding and fine polishing of various materials. Larger-sized synthetic diamond material sintered bodies can also be used in the field of high-hardness drill bits. The wear ratio range can even reach 1:3×10⁴-1:8×10⁴. The wear ratio range for wire drawing dies is 1: 10⁵-1:3×10⁵.

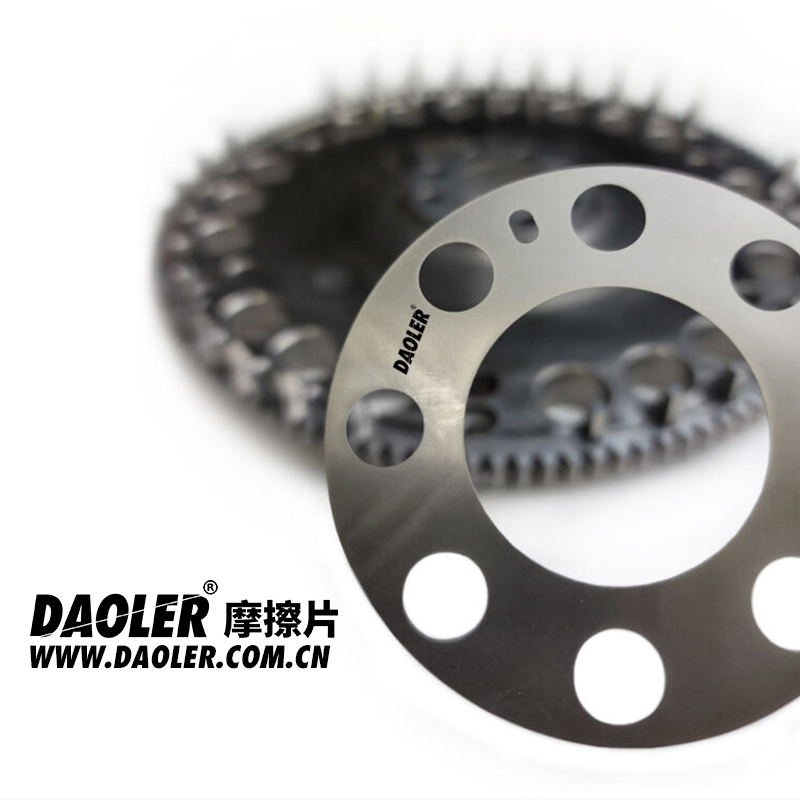

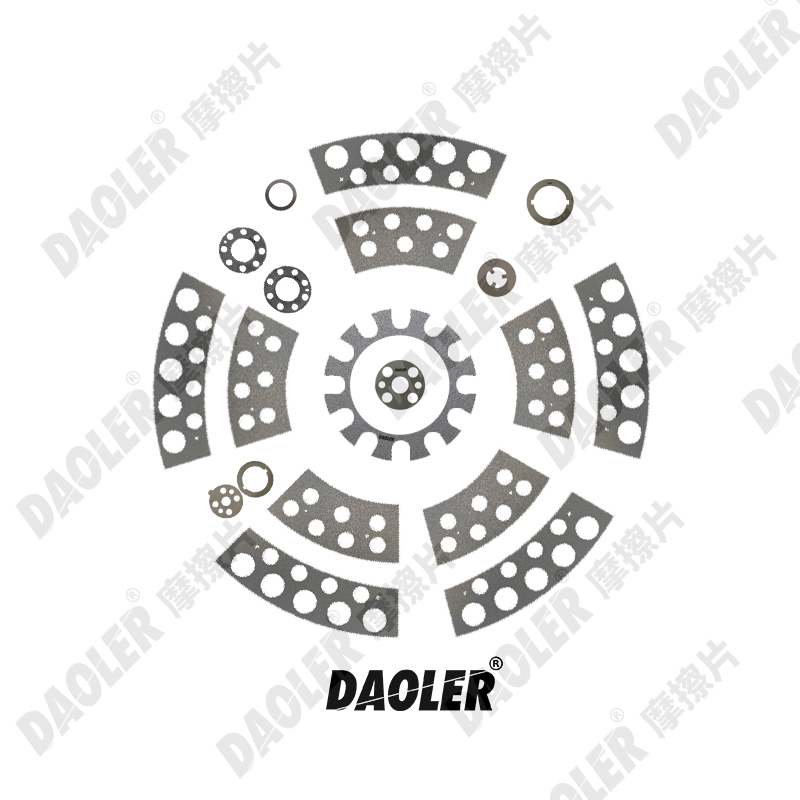

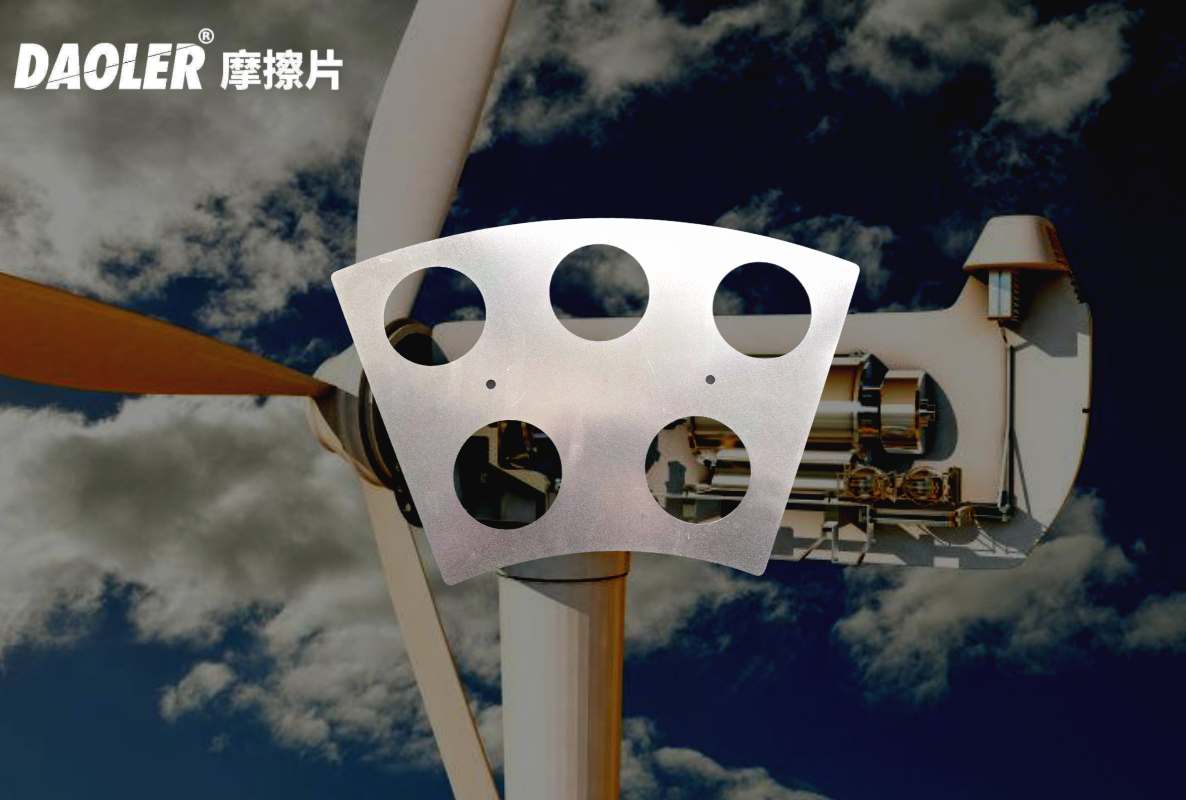

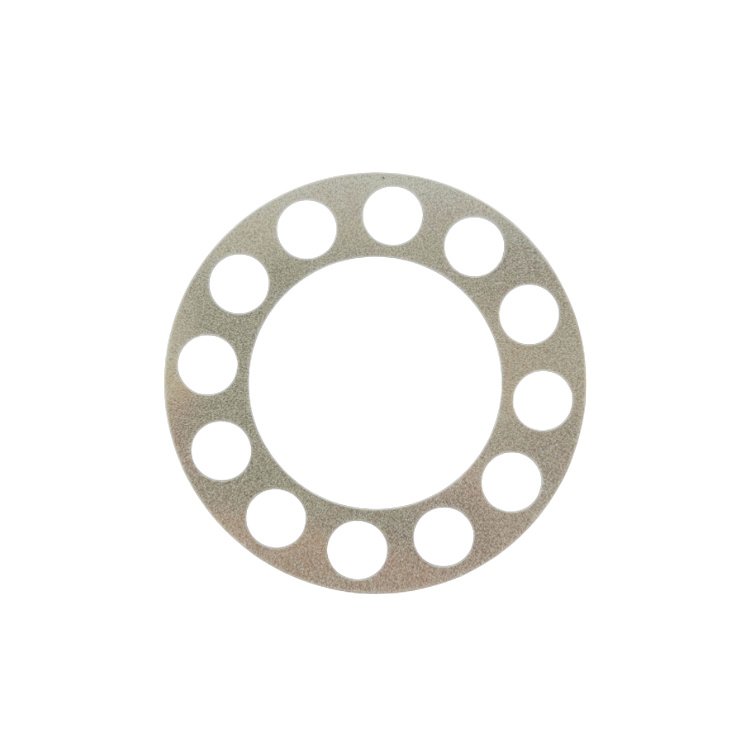

金刚石以其无与伦比的超高硬度,以及卓越的抗压与抗磨性能,成为制造各类切削工具、磨料、钻头和耐磨件的绝佳选择。此外,金刚石多晶镀层也被广泛应用于各类刀具和磨具,为其提供出色的耐磨涂层。其出色的弹性模量和声子振动特性,更使金刚石成为制作高质量表面压力传感器与声学传感器的理想之选,展现了其在多领域中的卓越应用价值。

Diamond, with its unparalleled ultra-high hardness and excellent resistance to pressure and wear, has become an excellent choice for manufacturing various cutting tools, abrasives, drill bits and wear-resistant parts. In addition, diamond polycrystalline coating is also widely used in various types of cutting tools and grinding tools to provide them with excellent wear-resistant coatings. Its excellent elastic modulus and phonon vibration characteristics make diamond an ideal choice for producing high-quality surface pressure sensors and acoustic sensors, demonstrating its excellent application value in many fields.

金刚石的力学性能使其成为一种独特的材料,在众多领域中都发挥着不可替代的作用。随着科技的不断发展,人们对金刚石性能的研究将更加深入,相信未来金刚石的应用领域将会更加广泛。无论是作为切削工具、磨料还是精密器件的耐磨涂层,金刚石都将以其卓越的力学性能继续为人类社会的发展做出贡献。

The mechanical properties of diamond make it a unique material that plays an irreplaceable role in many fields. With the continuous development of science and technology, people will conduct more in-depth research on the properties of diamond, and it is believed that the application fields of diamond will be more extensive in the future. Whether used as cutting tools, abrasives or wear-resistant coatings for precision devices, diamond will continue to contribute to the development of human society with its excellent mechanical properties.

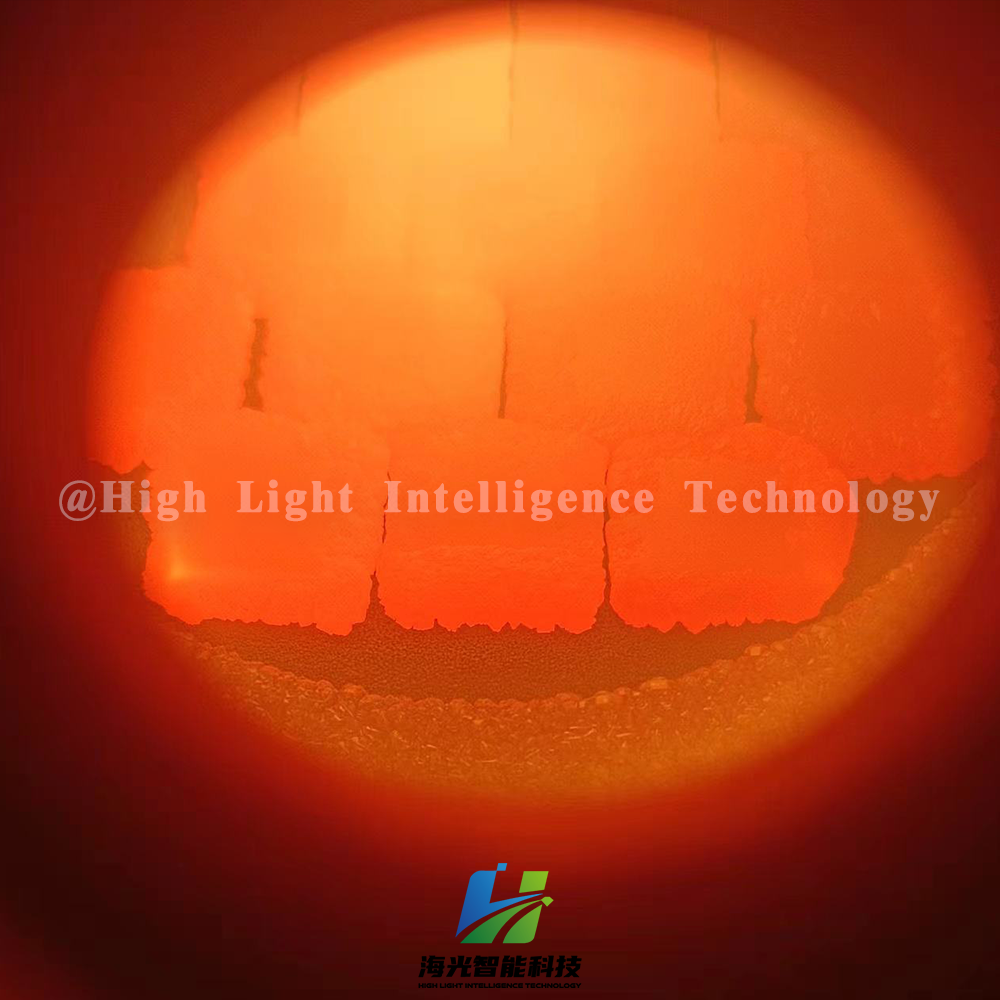

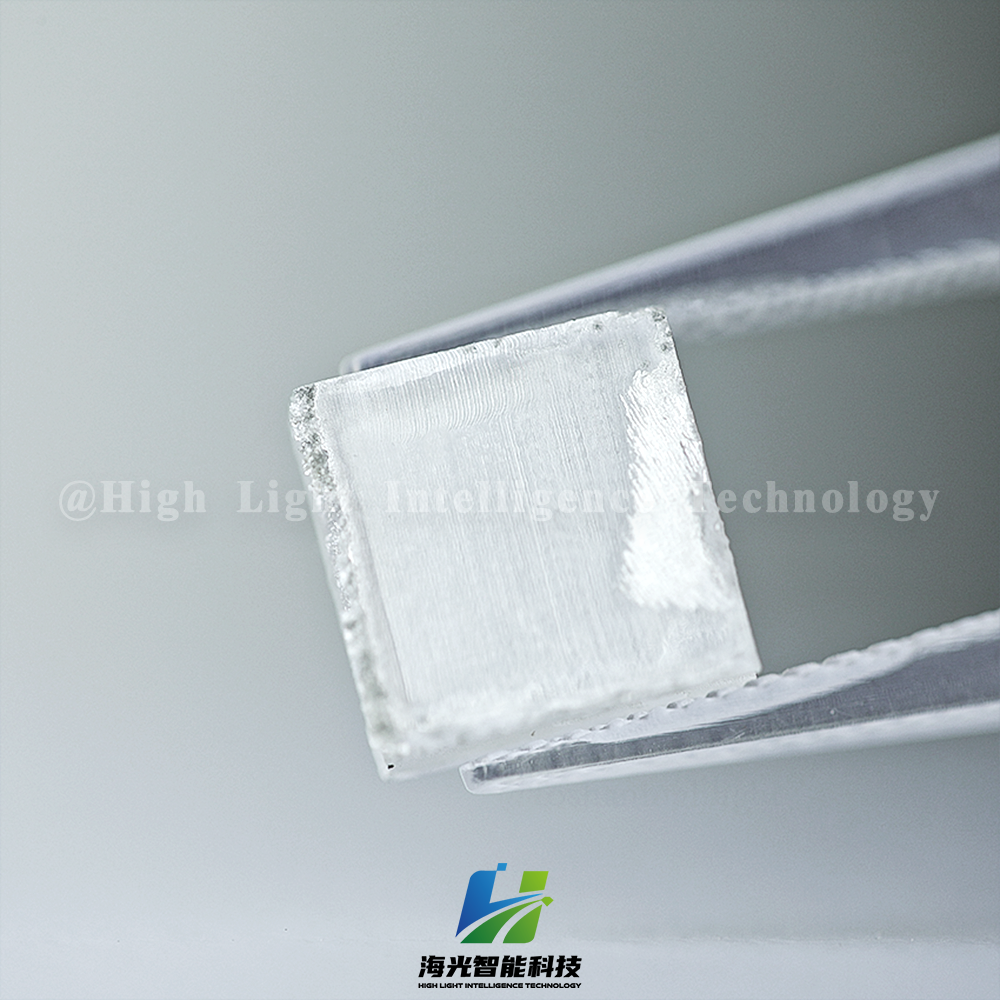

With MPCVD technology as its core, High Light Intelligence Technology has long been committed to the R&D and manufacturing of high-quality diamond materials and related equipment. It has advanced MPCVD equipment, laser processing equipment and precision polishing equipment. High Light Intelligence Technology's MPCVD technology equipment can produce high-quality diamond, thereby helping to improve the performance of integrated circuits. Our products and services are designed to provide customers with the best solutions to meet their needs for high quality diamond and integrated circuit performance.

*部分图片来自互联网,无法核实真实出处,如涉及侵权,请直接联系删除。

*Some pictures come from the Internet, and the true source cannot be verified. If there is any infringement, please contact us directly for deleti

请先 登录后发表评论 ~