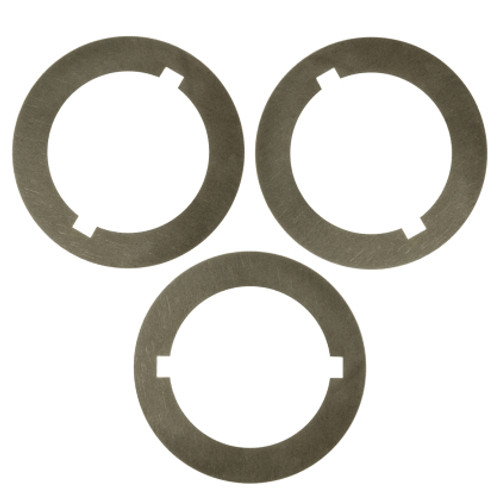

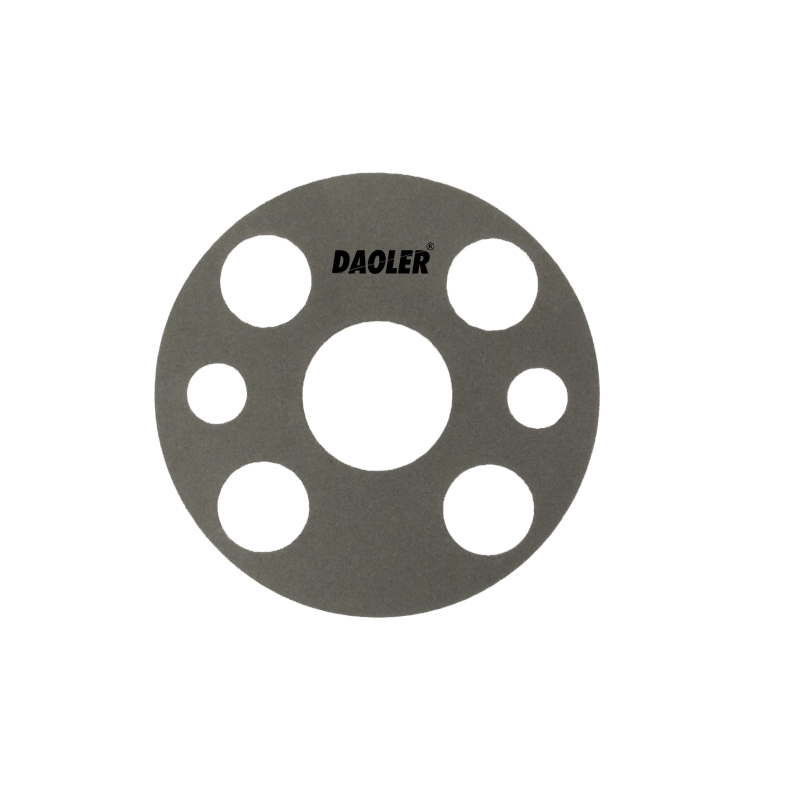

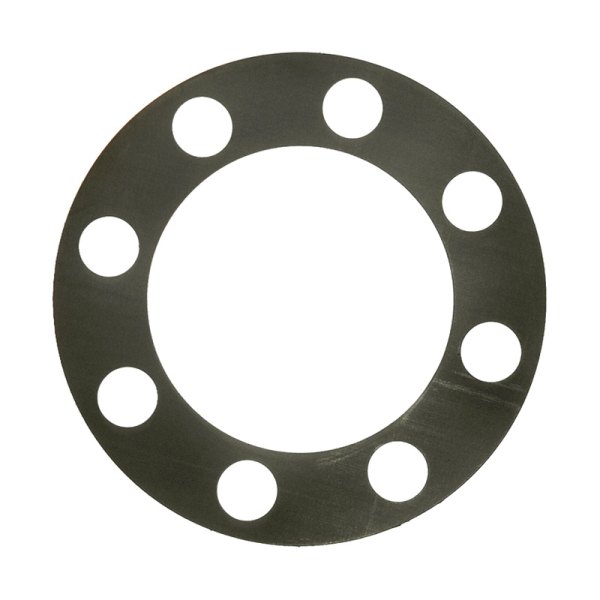

SHIM FRAME HIGH FRICTION 高摩擦垫片

术语“SHIM FRAME HIGH FRICTION”(高摩擦垫片框架)解析

“SHIM FRAME HIGH FRICTION”这一术语可能指一种将垫片(薄型间隔片或填充物)集成到框架结构中以提供高摩擦特性的组件或系统。以下是其潜在含义、应用场景及设计考量的详细解析:

核心概念

垫片(Shim):用于对齐、间隔或调整的薄型材料(金属、塑料、橡胶、复合材料)。

框架(Frame):结构组件(如机械、车辆、门窗、自行车、电子设备中的框架)。

高摩擦(High Friction):增强抓地力或阻力,防止滑动或位移。

潜在应用场景

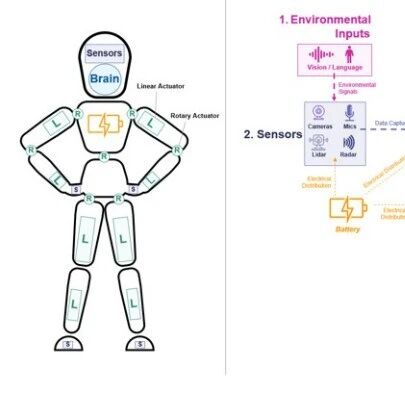

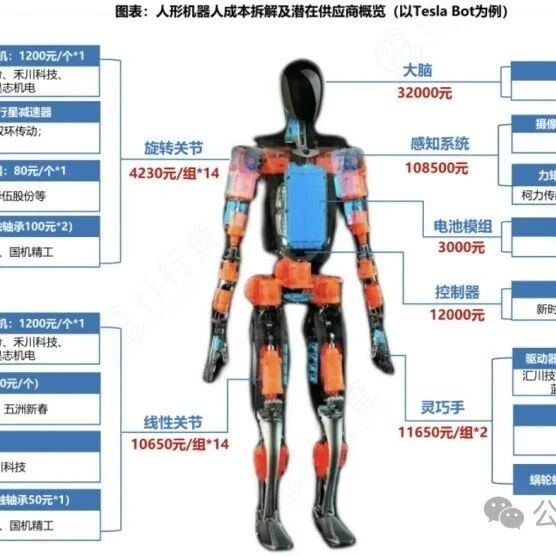

机械/工业系统:

机械对齐:高摩擦垫片防止框架因振动松动(如电机、泵体)。

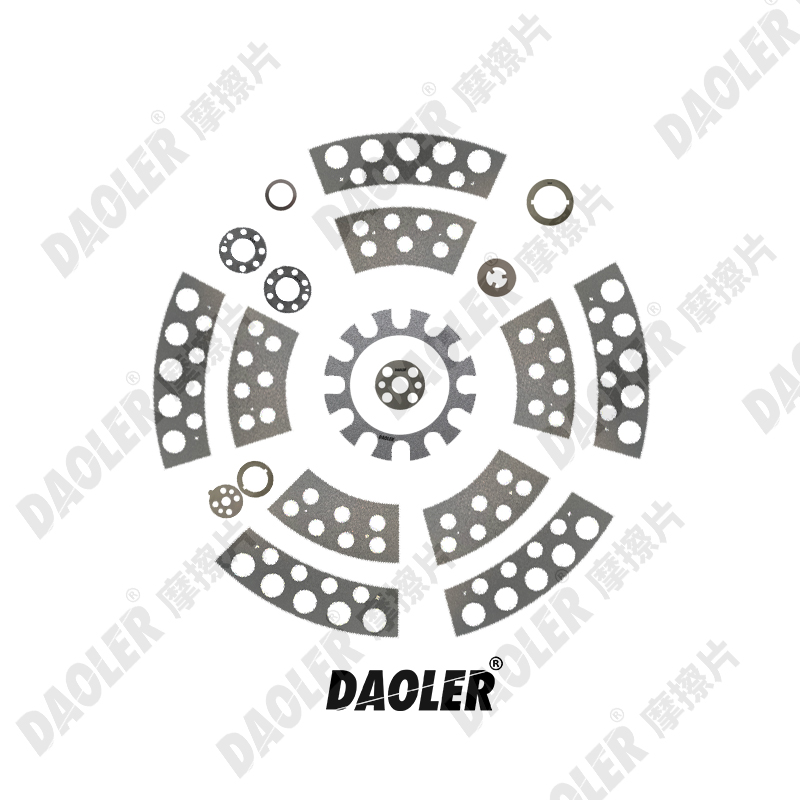

制动系统:刹车卡钳框架中使用垫片以减少噪音并增强刹车片抓力。

航空航天:飞机装配中采用垫片框架以吸收振动并保持结构稳定。

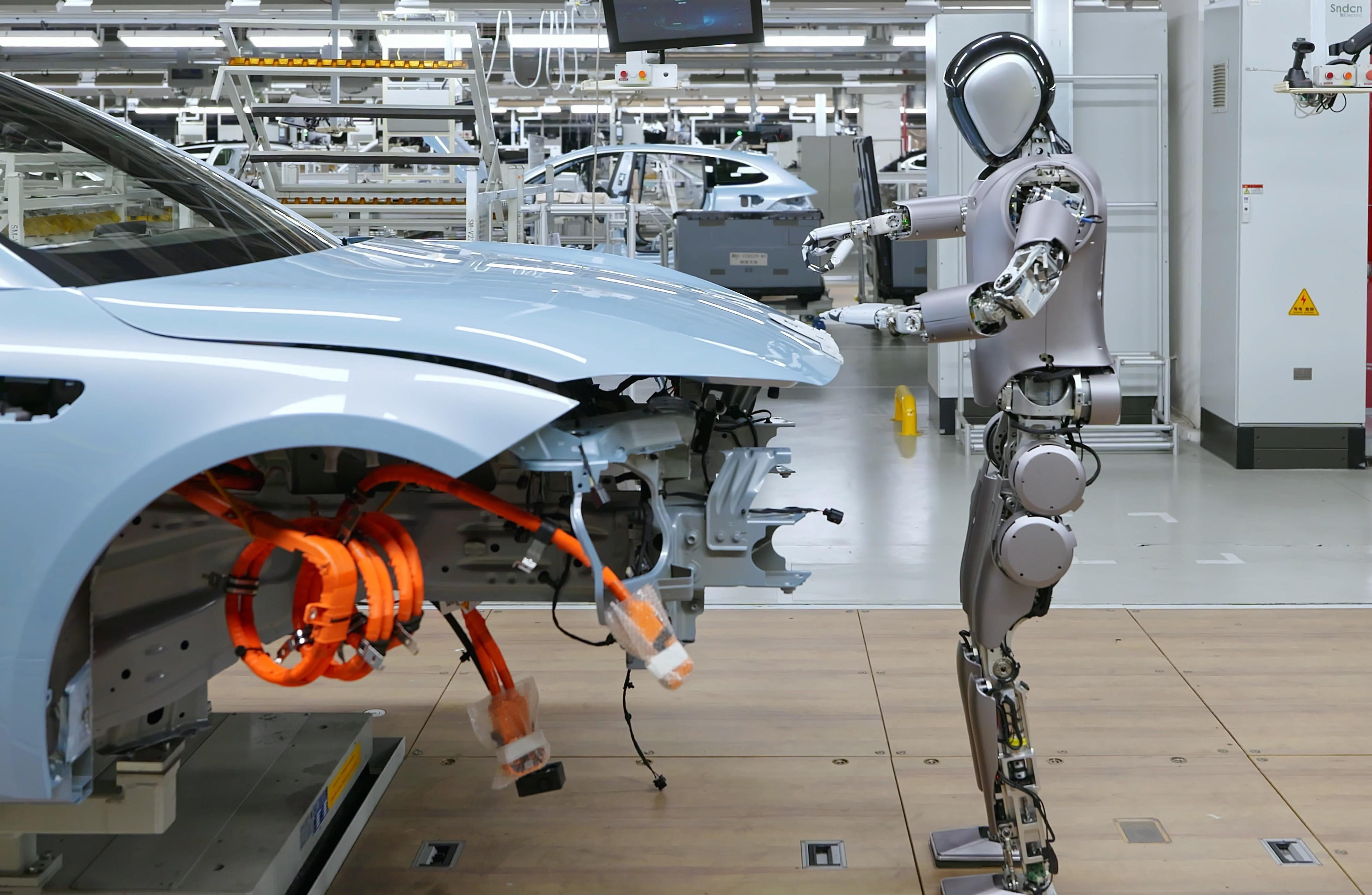

汽车领域:

悬架或底盘框架使用带纹理或橡胶涂层的垫片以缓冲运动。

电动车电池框架中采用防滑垫片提升稳定性。

建筑工程:

门窗框架使用垫片调整安装间隙并防止移位(如橡胶垫片)。

钢结构框架中采用高摩擦垫片以增强抗震性能。

消费品:

自行车框架使用垫片固定组件(如座管、把手)。

家具组装中通过高摩擦垫片提高稳定性。

电子/制造业:

夹具或工装中使用防滑垫片以固定零件(如加工或3D打印场景)。

高摩擦垫片材料

橡胶/弹性体:天然抓地力,减震(如EPDM橡胶、硅胶)。

复合材料:表面带纹理的纤维增强聚合物。

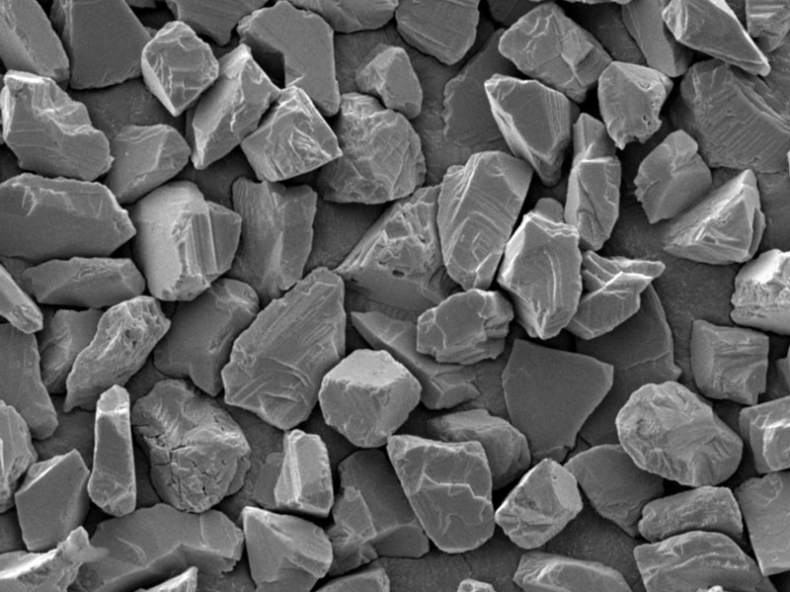

涂层金属:喷砂处理的阳极氧化铝或钢。

工程塑料:含摩擦控制添加剂的超高分子量聚乙烯(UHMWPE)或聚四氟乙烯(PTFE)。

设计考量

表面纹理:滚花、凹槽或粘合层以增强摩擦。

环境耐受性:耐高温、防潮或耐化学腐蚀(如汽车或户外场景)。

承重能力:确保材料能承受压力而不变形。

常见问题解决

垫片滑动:更换为高摩擦材料或使用胶粘剂(如乐泰®胶)。

对齐问题:结合螺栓/夹具进行冗余固定。

The term "SHIM FRAME HIGH FRICTION" likely refers to a component or system where a shim (a thin spacer or filler) is integrated into a frame structure to provide high friction properties. Here's a breakdown of possible interpretations, applications, and considerations:

Key Concepts

Shim: A thin material (metal, plastic, rubber, composite) used for alignment, spacing, or adjustment.

Frame: A structural component (e.g., machinery, vehicles, doors, bicycles, electronics).

High Friction: Enhanced grip/resistance to prevent slippage or movement.

Potential Applications

Mechanical/Industrial Systems:

Machinery Alignment: High-friction shims prevent vibration-induced loosening in frames (e.g., motors, pumps).

Brake Systems: Shims in brake caliper frames to reduce noise and improve pad grip.

Aerospace: Shimmed frames in aircraft assemblies to absorb vibrations and maintain structural integrity.

Automotive:

Suspension or chassis frames using textured or rubber-coated shims to dampen movement.

Battery frames in EVs with anti-slip shims for stability.

Construction:

Door/window frames with shims to adjust fit while preventing shifting (e.g., rubberized shims).

Structural steel frames with friction-enhancing shims for seismic resistance.

Consumer Goods:

Bicycle frames with shims to secure components (e.g., seat posts, handlebars).

Furniture assembly using high-friction shims for stability.

Electronics/Manufacturing:

Fixtures or jigs with non-slip shims to hold parts in place during machining/3D printing.

Materials for High-Friction Shims

Rubber/Elastomers: Natural grip, vibration damping (e.g., EPDM, silicone).

Composite Materials: Fiber-reinforced polymers with textured surfaces.

Metal with Coatings: Anodized aluminum or steel with grit-blasted finishes.

Thermoplastics: UHMWPE or PTFE with additives for friction control.

Design Considerations

Surface Texture: Knurling, grooves, or adhesive layers to enhance grip.

Environmental Resistance: Heat, moisture, or chemical compatibility (e.g., automotive/outdoor use).

Load Capacity: Ensure the shim material can withstand compressive forces without deforming.

Troubleshooting Tips

If a shim slips, consider upgrading to a high-friction material or adding adhesives (e.g., Loctite®).

For alignment issues, combine shimming with bolts/clamps for redundancy.

Need More Context?

If this relates to a specific industry or problem (e.g., automotive, construction, DIY), provide details for a targeted solution!

请先 登录后发表评论 ~