Nature Communications法国国家科学研究中心:卓越强韧性和耐磨性的磁控溅射Al2O3/Al纳米复合层

“Al₂O₃/Al hybrid nanolaminates with superior toughness, strength and ductility” 一文报道了一种新型氧化铝 / 铝纳米层压板(Al₂O₃/Al NLs),其厚度小于 100nm 的氧化铝层与铝中间层堆叠时,展现出卓越的力学性能,包括高韧性、强度和延展性,为氧化铝在更多领域的应用提供了可能。

https://doi.org/10.1038/s41467-025-56512-7

研究背景

在材料力学领域,材料的强度 - 延展性平衡和断裂韧性是关键性能指标。传统上,减小材料尺寸或内部结构尺寸可提高强度,但往往导致延展性降低,且高的强度 - 延展性平衡并不一定意味着高断裂韧性。

对于薄涂层,需要兼具高硬度、足够的延展性和高断裂韧性以抵抗磨损、划痕等,然而增强涂层断裂韧性面临材料厚度限制等困难,因此创造兼具这三种性能优势的新型涂层是研究目标。

实验表征方法

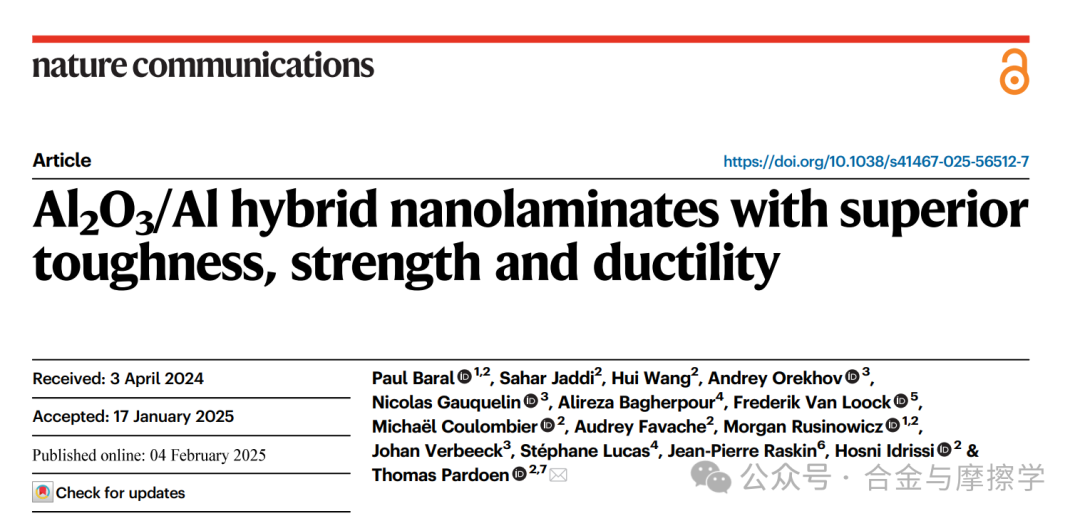

制备过程:利用直流磁控溅射在室温及 1.5mTorr 压力下,以 300mA 电流从 99.9995% Al 靶材沉积 Al₂O₃/Al NLs。通过改变气体混合物(Al 层用纯 Ar,Al₂O₃层用 Ar/O₂)来形成层状结构,并根据沉积前测量的溅射速率调整沉积时间,制备了不同厚度组合的样品,包括用于压痕和摩擦测试的厚堆叠样品以及用于原位 TEM 和芯片测试的 3 层或 5 层基本堆叠样品。

成分与微观结构:使用双束聚焦离子束(FIB)制备横截面薄片,经 Pt 保护后,用透射电子显微镜(TEM)、扫描透射电子显微镜(STEM)、能量色散 X 射线光谱(EDX)和电子衍射(ED)进行分析,确定了层状结构、Al₂O₃的非晶性质、界面粗糙度及元素分布等。

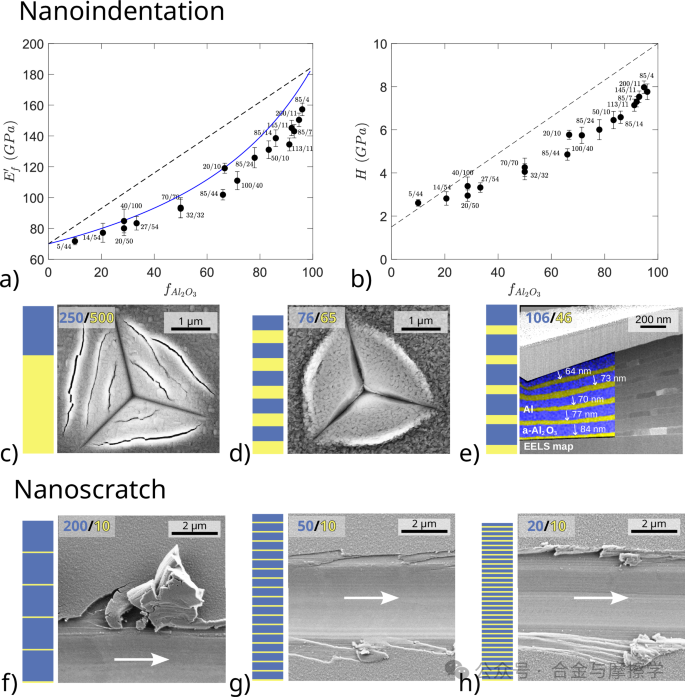

力学性能:采用纳米压痕仪(G200)测量硬度和弹性模量;利用纳米划痕仪研究摩擦性能和涂层失效机制;通过原位 TEM 拉伸实验(使用 PTP 装置)获得应力 - 应变曲线;基于微电子 / MEMS 工艺制备芯片测试结构,测定断裂韧性。

实验结果

微观结构:Al 层呈柱状晶粒形态,Al₂O₃层为非晶态,界面粗糙度低且具有良好的相干性。

Fig. 1: Deposition and TEM characterization of Al2O3/Al NLs.

a Principle of deposition method via DC magnetron sputtering; b bright-field TEM image of 50/10 NL specimen. The inset shows a high-resolution TEM image of the Al/Al2O3/Al interface together with Fast Fourier Transforms (FFTs) from the yellow squares. The coloured EELS map shows layers of aluminum (yellow) alternating with amorphous alumina (oxygen in blue). The Al2O3 layers are fully amorphous. Note also the good coherency of the Al/Al2O3 interfaces with limited undulations.

力学性能

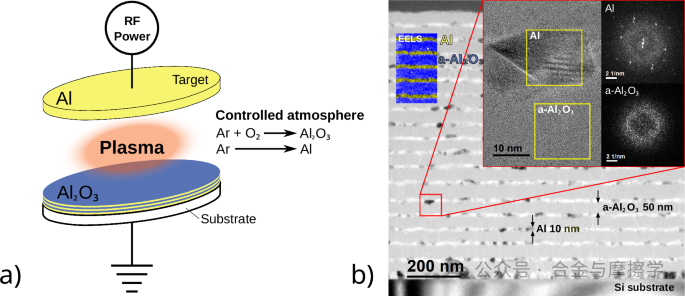

纳米压痕测试表明,弹性模量随 Al₂O₃含量变化接近 Reuss “等应力” 行为,硬度随 Al₂O₃含量增加而非线性上升,最高可达 8GPa。Al 层在厚度减小时通过剪切流适应变形,使硬度低于混合法则预期。

Fig. 2: Tribological behavior of Al2O3/Al NLs.

Determination via nanoindentation of a the elastic modulus, the dashed line represents the Voigt “iso-strain” rule of mixture, the blue curve represents the analytical Reuss “iso-stress” rule of mixture and b nanohardness as a function of the volume fraction of Al2O3 (with precise NL constituent thicknesses indicated on the plot), the dashed line represents the linear evolution of hardness from pure Al to pure Al2O3; c, d SEM top view micrographs of indents for a NL with thick layers and with thin layers respectively (with Al2O3 in blue and Al in yellow); e focused ion beam cross-section below an indent imaged by HAADF-STEM superimposed by EELS map, showing the extreme deformation of the NL layers without failure; f–h SEM top view micrographs of nanoscratch tracks.

纳米划痕测试显示,Al₂O₃厚度小于 100nm 的样品无裂纹,而厚层样品出现径向裂纹,表明其具有良好的增韧和延展效果。

原位 TEM 拉伸实验测得多层结构的断裂应变约 7%,强度高于 3GPa,且 Al 层能阻止裂纹扩展。芯片裂纹测试得出 50/10 和 50/20 NLs 的平均断裂韧性 为 ,对应 约为 ,远高于块状 Al₂O₃。

Fig. 3: In situ TEM mechanical testing of Al203/Al NLs.

a True stress true strain uniaxial tension response of the three systems 50/10,100/10 and 150/100 Al2O3/Al NLs; b push to pull (PTP) frame with BF-TEM magnifications on the three tested NLs; c higher magnification of the undeformed 50/10 NL on the left and after fracture on the right, with transverse cracks in Al2O3 indicated by yellow arrows, arrested by the Al interlayers.

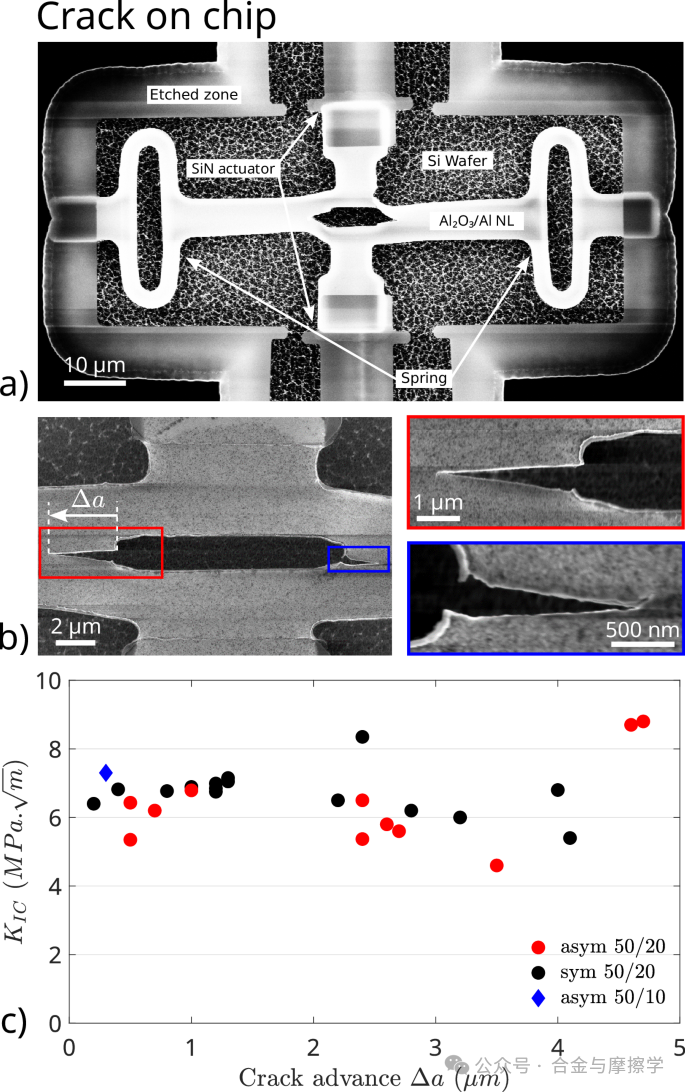

Fig. 4: Fracture toughness of Al203/Al NLs through crack on chip testing.

a Global view showing the SiN actuator beams pulling after release on the long central NL structure containing an elliptical hole (the structure includes two springs on both side to release the residual stresses in the crack propagation direction to avoid any T-stress); b zoom of the cracks initiated at the notch roots and arrested at some distance further from which the fracture toughness is determined by finite element simulations; c variation of KIc with crack advance (one point is one specimen) for the 50/20/50 symmetric and asymmetric test structures, and one 50/10/50 asymmetric test structure.

结果讨论

性能优势机制:Al₂O₃/Al NLs 的高性能源于多种机制协同作用。薄 Al₂O₃层自身具有高延展性和内在韧性,Al 层可阻止裂纹扩展、提供剪切变形能力,二者结合实现了稳定的塑性变形、裂纹止裂和超剪切效应,有效分散应力、消耗能量,从而提高了材料的综合性能。

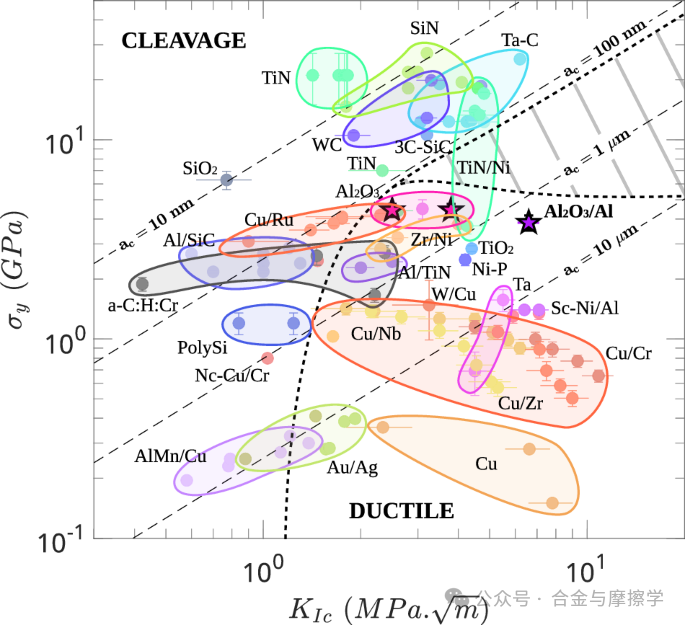

与其他材料对比:通过文献调研对比,该 NLs 在强度高于 1GPa 的材料体系中具有最高的断裂韧性,在强度 - 韧性图中表现突出,为其在高摩擦性能涂层应用(如抗腐蚀)提供了优势。

Fig. 5: Yield strength σy as a function of fracture toughness KIc of single and multilayer thin films reported in the literature, see Supplementary Note 8.

The error bars are extracted directly from the referenced sources. Measurement data on the deposition sputtered single layer Al2O3 film and the Al2O3-Al-Al2O3 laminate film produced in this work are included with star symbols. The dashed lines are contours of equal critical crack length ac, defined in the supplementary Note 8. The dotted line divides the map into two fracture mode regimes; the hatched region highlights a strength-toughness regime for which no representative material system could be identified.

该研究制备的 Al₂O₃/Al 纳米层压板在力学性能上取得了显著突破,其独特的微观结构和多种增韧、强化及延展机制为高性能涂层材料的设计提供了新思路,有望在众多领域得到广泛应用。

请先 登录后发表评论 ~