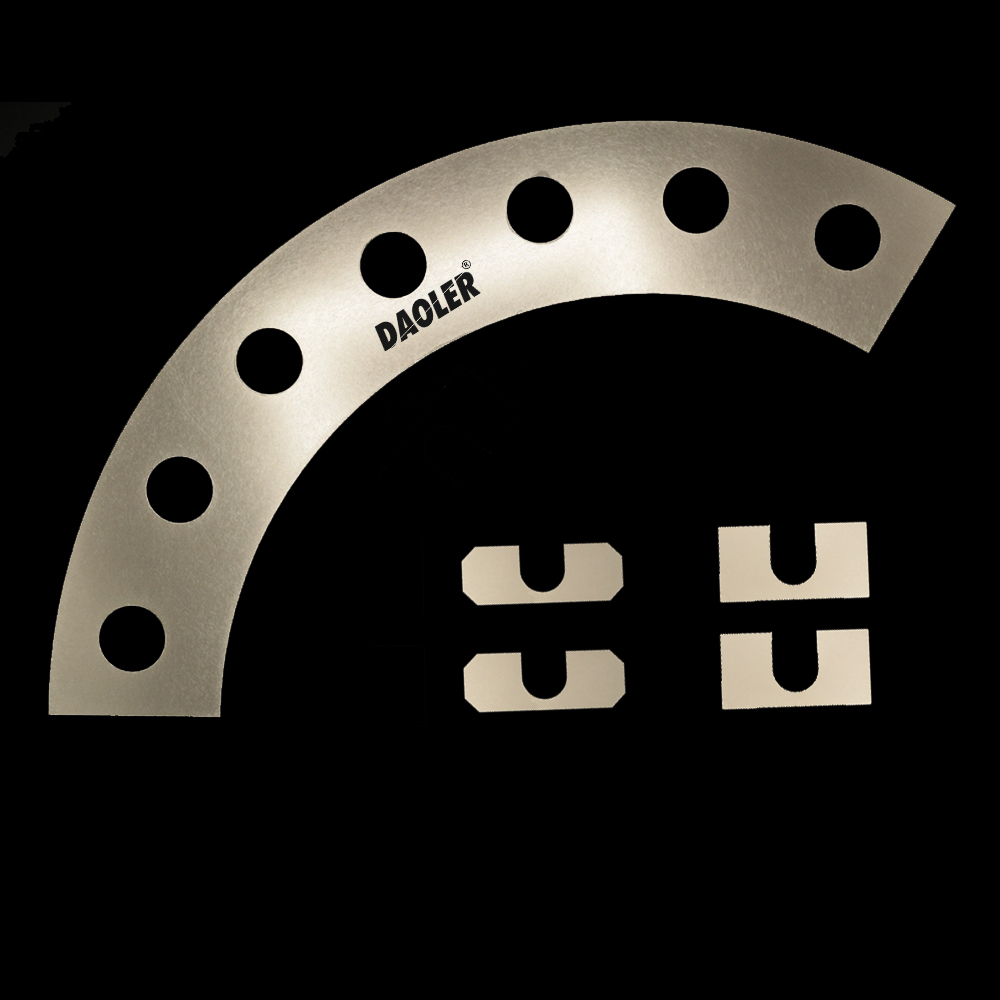

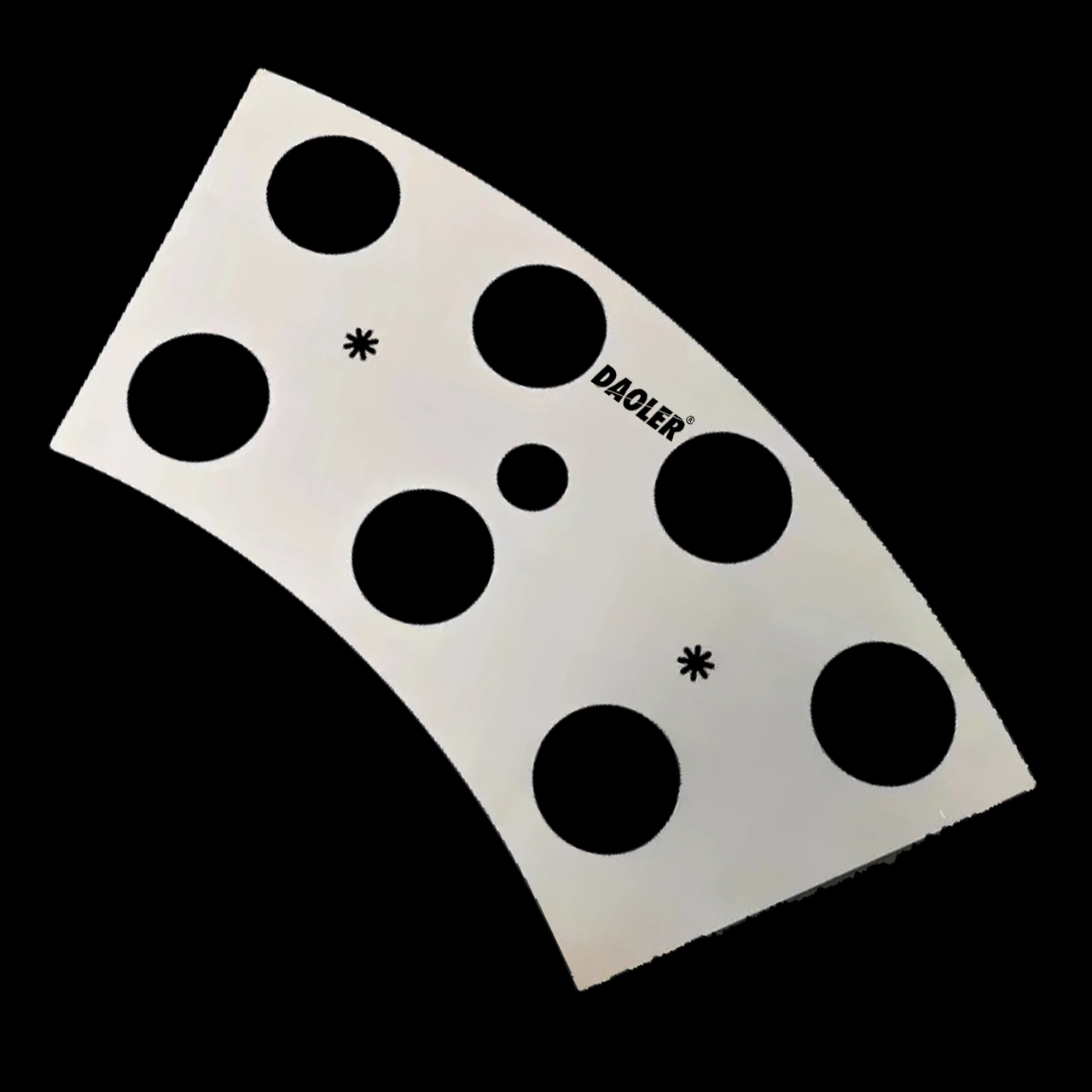

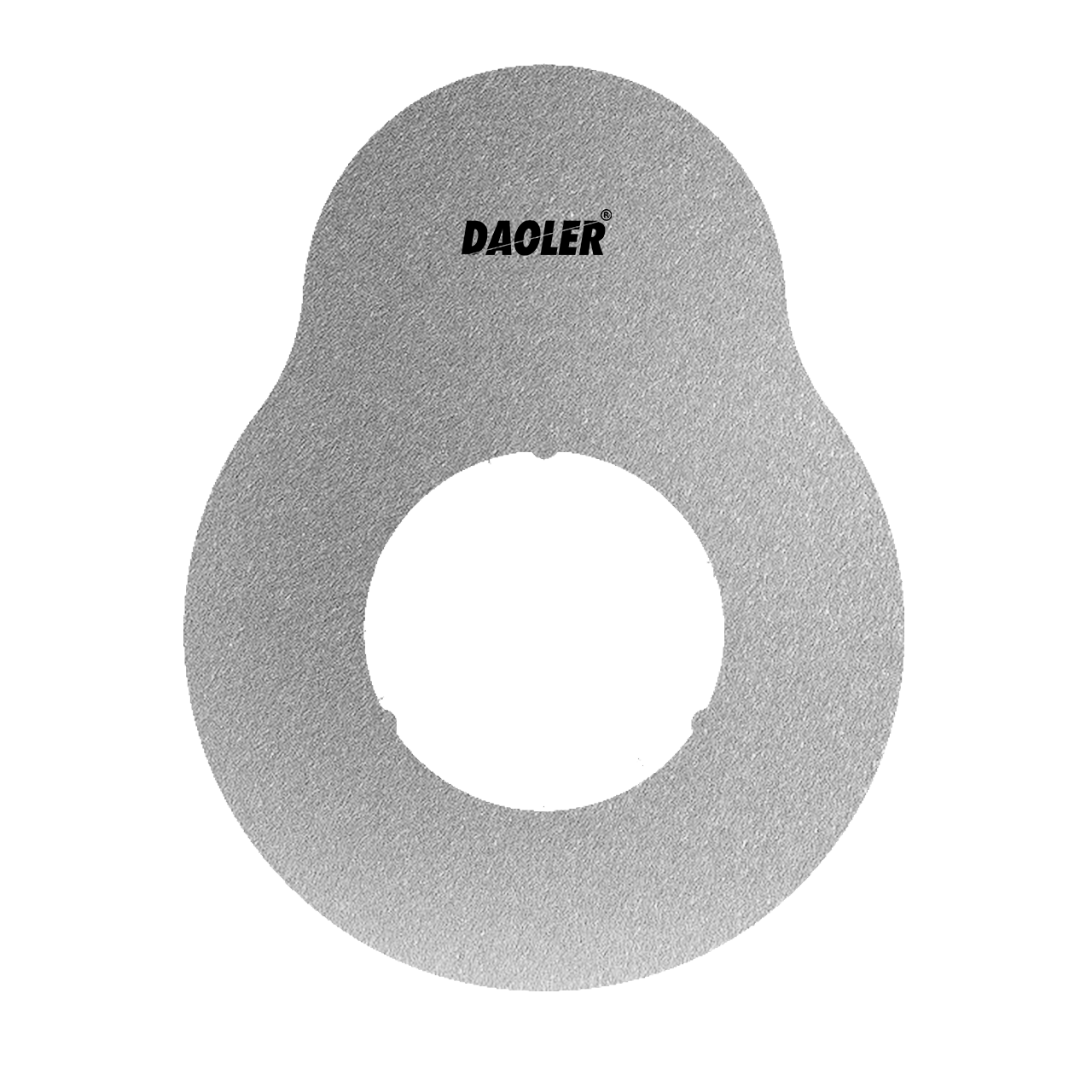

Technological Innovation: How DAOLER® Diamond Friction Spacers Become the Core Engine for Robot Joint Miniaturization

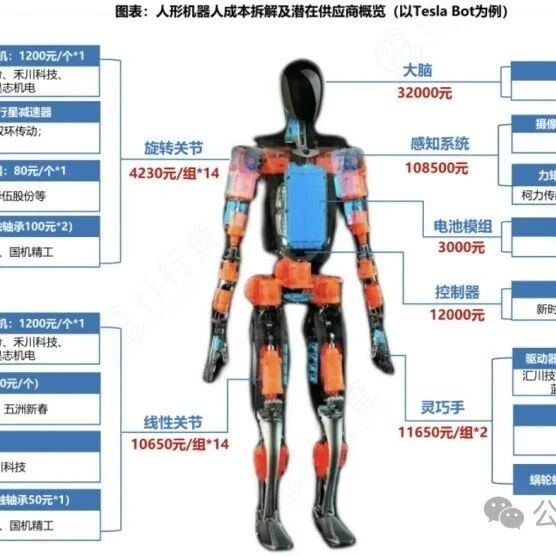

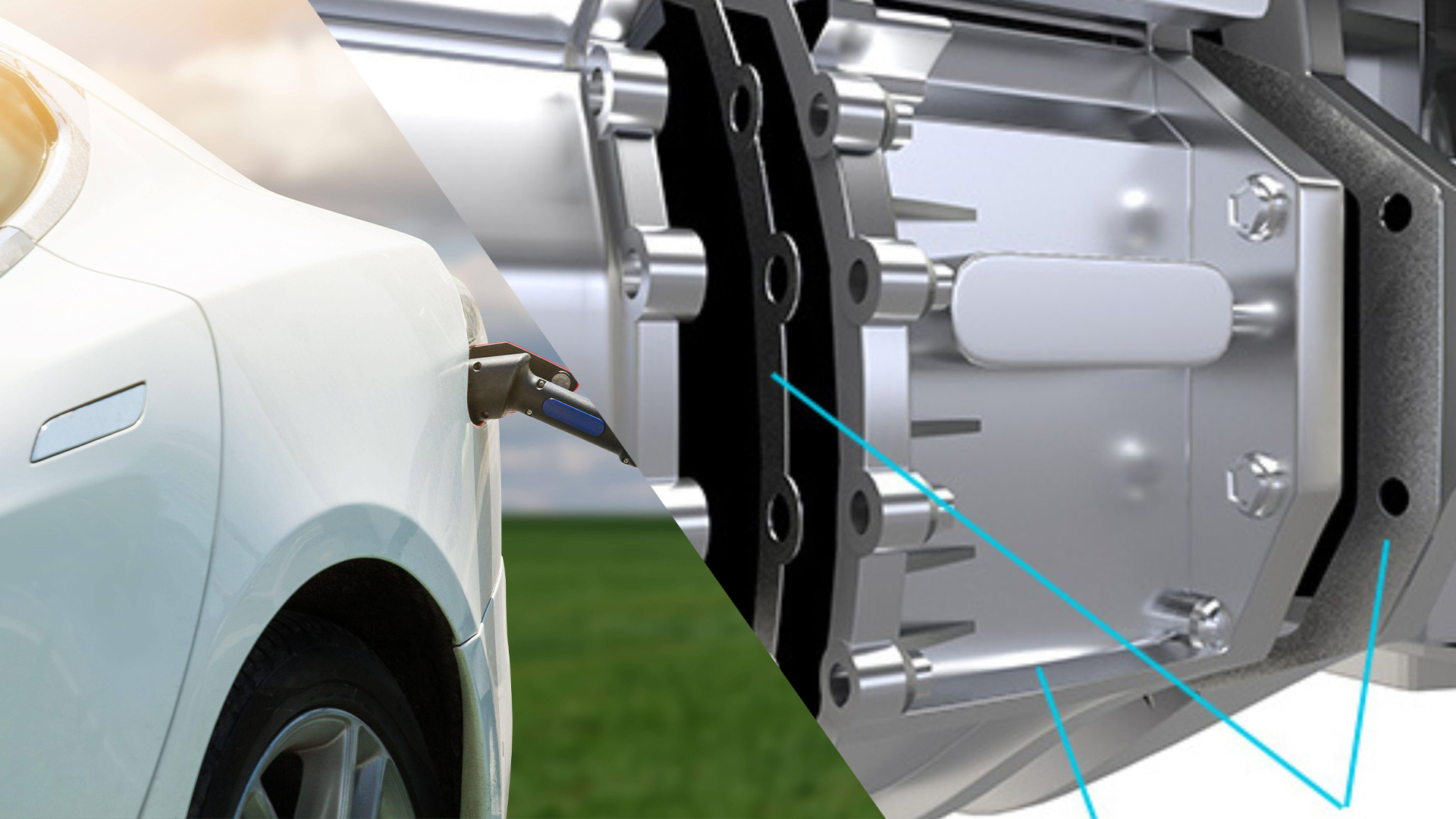

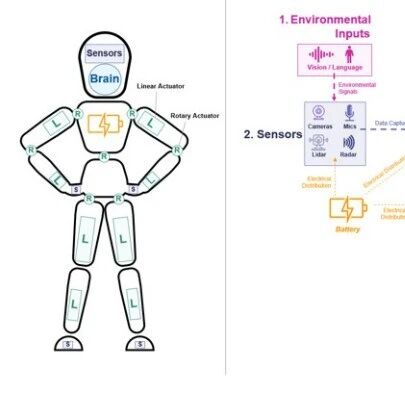

In the field of robot design and manufacturing, a race for "every inch of space is precious" never stops. Especially in cutting-edge areas like collaborative robots, medical robots, and humanoid robots, engineers relentlessly pursue the same goal: achieving greater output torque, higher precision, and longer lifespan within a smaller space. Traditional joint designs, reliant on large contact area connection methods, have become a bottleneck restricting the reduction of component size. The emergence of the DAOLER® Diamond Friction Spacer provides a groundbreaking solution from the aspects of materials science and tribology.

I. Technical Bottleneck: Why Traditional Connection Methods Hinder Joint Miniaturization?

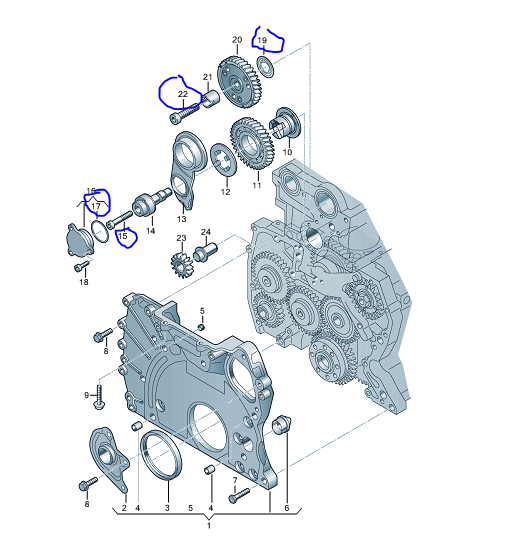

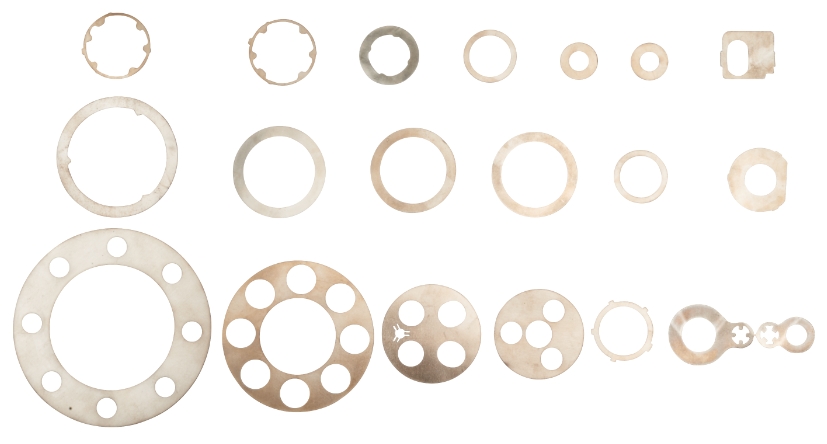

The core transmission components of a robot joint, such as the harmonic reducer output end, need to achieve zero-backlash, high-rigidity connection with the arm or the next joint. Traditional solutions primarily rely on:

Interference Fits: Require extremely high machining precision and significant press-fit force, easily damaging precision components, difficult to disassemble, and offer no resistance to fretting wear.

Spline Connections: Can transmit high torque but involve complex machining, have minimal backlash, and require large flange radial dimensions to accommodate the spline structure.

The common issue with these methods is: to ensure connection reliability, they must seek "stability" through "largeness," increasing the contact area or structural volume to compensate for low connection efficiency. This not only results in bulky joints but also triggers a "chain reaction" – larger flanges require larger bearings and heavier housings, ultimately preventing the robot joint module from slimming down.

II. DAOLER® Diamond Friction Spacers: Breaking the Impasse with Materials Science

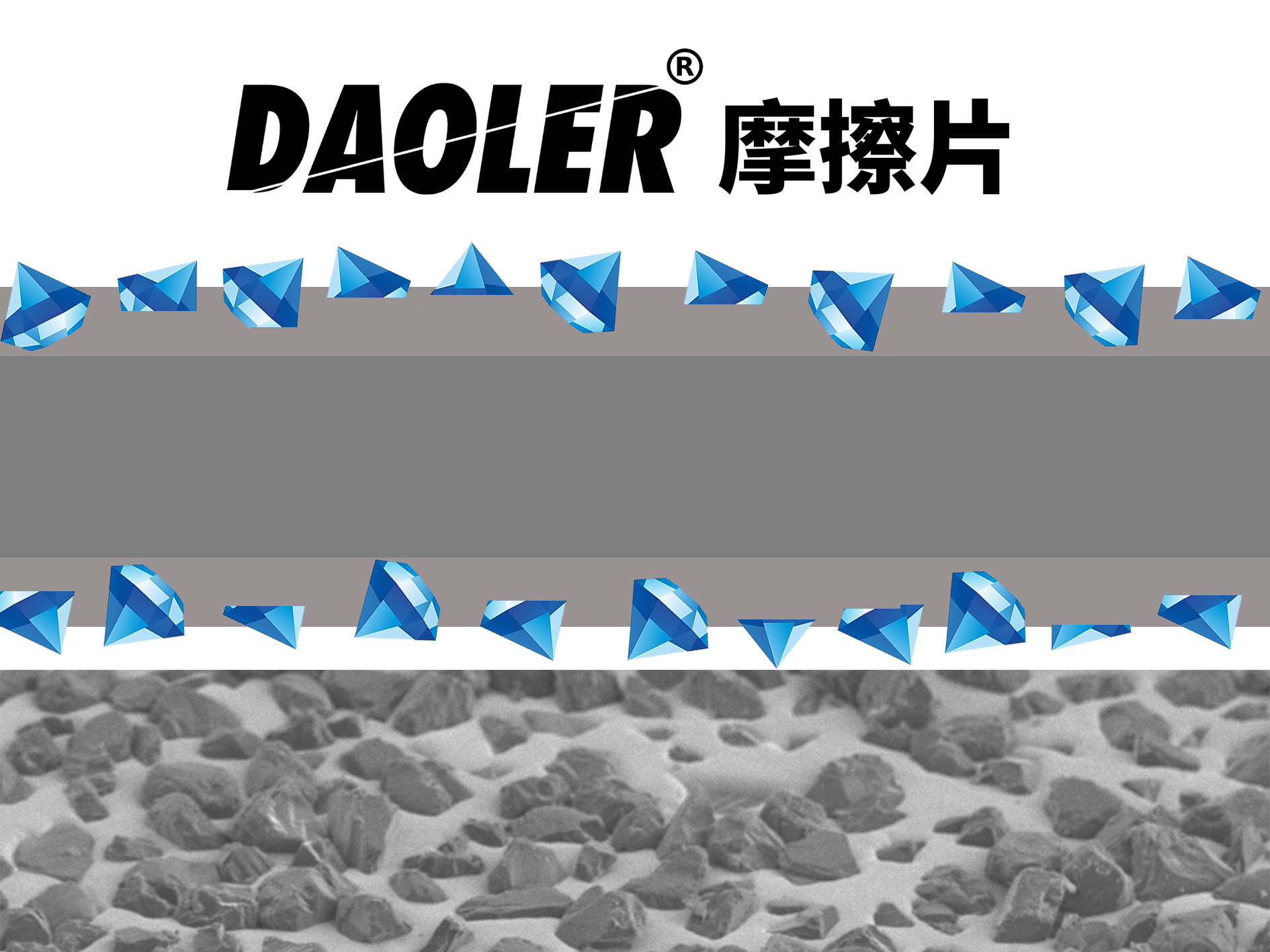

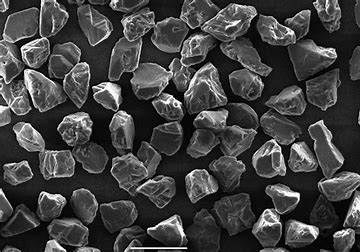

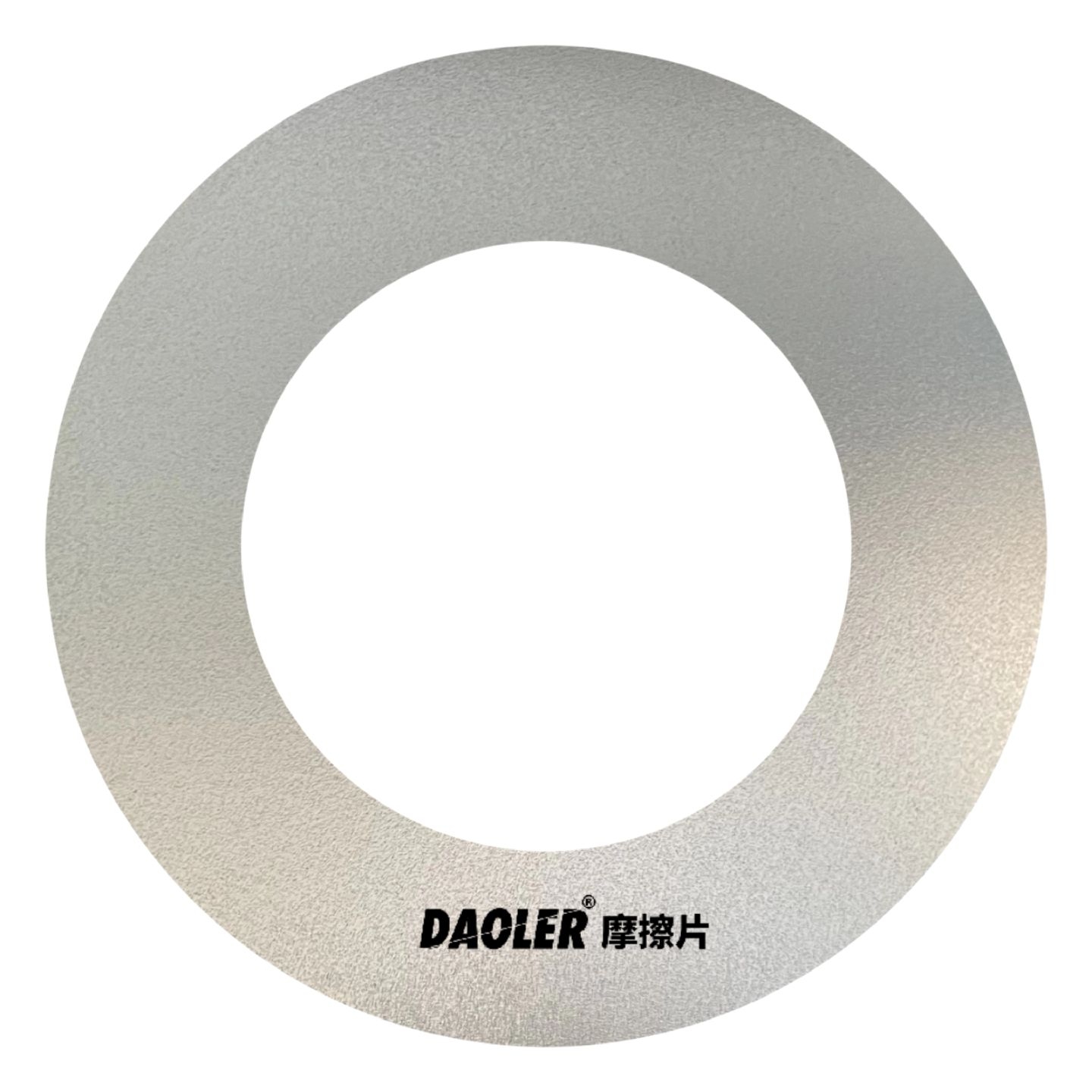

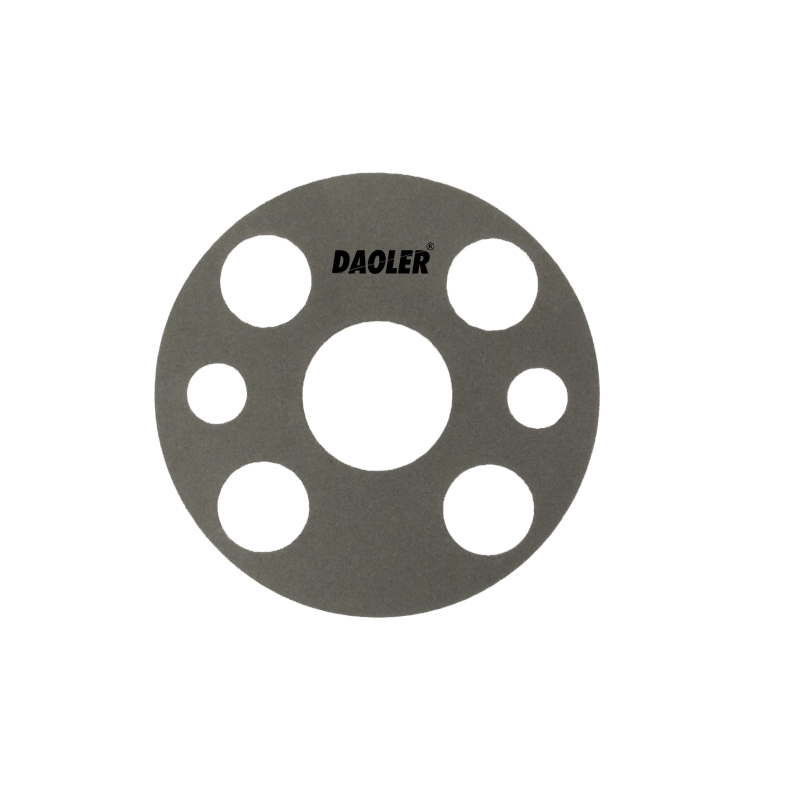

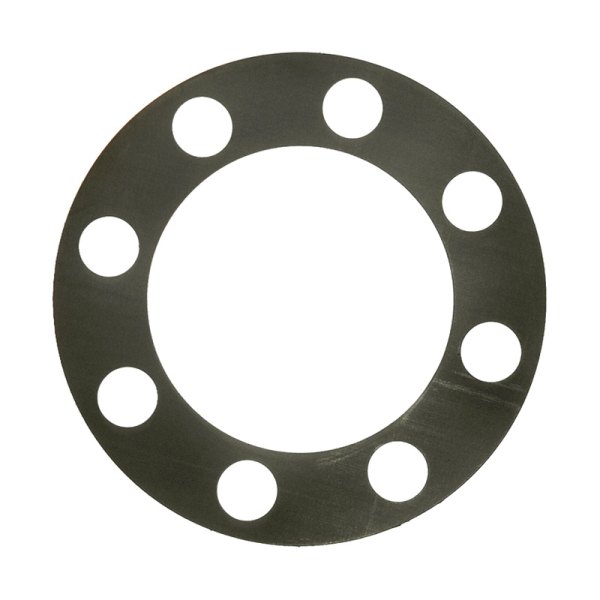

DAOLER®'s solution is not a simple material substitution but a redefinition of the physical essence of joint connection. Its core technology lies in the adoption of nanodiamond composite coating technology, growing a layer of extremely hard and excellent friction-performance surface on a special alloy steel substrate.

From a technical perspective, how does it achieve "small contact area, high load capacity"?

1. Exceptional Coefficient of Friction (μ), Rewriting the Formula of Force and Area

According to Coulomb's law of friction F = μ × N, the transmittable friction force (F) is proportional to the coefficient of friction (μ) and the normal pressure (N). The typical steel-on-steel coefficient of friction is about 0.1-0.15, while the DAOLER® Diamond Friction Spacer maintains a stable dynamic coefficient of friction above 0.20.

Technical Significance: This means that for transmitting the same torque (F), using the DAOLER® spacer allows:

Significant reduction in required bolt preload (N): Enables designers to use smaller规格, fewer bolts, thereby reducing flange thickness and bolt circle diameter.

Direct reduction of effective contact area (A): With a given preload N, a higher μ means greater friction force can be generated per unit area. Therefore, a precisely calculated, smaller annular contact area can handle the torque transmission task that previously required a large area.

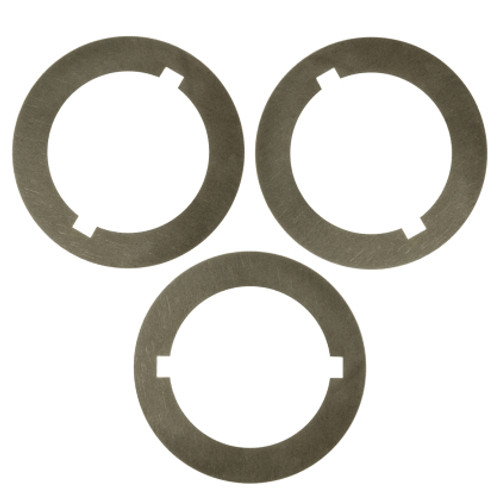

2. Ultimate Compressive Strength and Wear Resistance, Ensuring Uniform Surface Pressure and Long-Term Stability

Robot joints undergo significant alternating loads during dynamic operation. Ordinary friction spacers may plastically deform or wear under high pressure, leading to preload relaxation and connection failure.

DAOLER® Advantage: Diamond is the hardest natural material. The surface Vickers hardness of DAOLER® spacers exceeds Hv 3000, and their compressive strength far surpasses conventional copper-based or polymer spacers.

Achieves Ultra-High Surface Pressure Contact: It can withstand contact pressures exceeding 300 MPa without crushing, ensuring that under high preload, the microscopic peaks on the contact surface are uniformly flattened, forming a true "area contact" with even stress distribution.

Eliminates Fretting Wear: Under long-term vibrational loads, minute relative motion, or "fretting," occurs between metal connections, which is the culprit behind connection loosening and loss of precision. The extreme wear resistance of the DAOLER® diamond coating acts as a solid barrier, completely "isolating" fretting wear within the spacer layer, protecting the expensive harmonic reducer flange and connecting components, and ensuring the joint's connection stiffness and repeat positioning accuracy throughout its entire lifecycle.

3. Excellent Thermal Stability, Addressing Joint Internal Temperature Rise Challenges

During high-duty operation, motors and reducers generate heat, causing the internal temperature of the joint to rise. The frictional performance of ordinary organic material spacers deteriorates rapidly with increasing temperature.

DAOLER® Response: The diamond coating possesses excellent thermal stability, maintaining a stable coefficient of friction across a wide temperature range from -50°C to 500°C. This allows robot joints equipped with DAOLER® spacers to maintain constant torque transmission capability and connection reliability even under extreme conditions or after prolonged continuous operation, providing a solid safety margin for compact design.

III. Design Transformation: How DAOLER® Helps Engineers Achieve Size Breakthroughs?

Integrating the DAOLER® Diamond Friction Spacer has led to revolutionary simplification and optimization in robot joint design:

Extremely Simplified Flange Design: No need for complex spline machining or thick walls for interference fits. The connecting flange can be designed thinner, with a smaller diameter, becoming a lightweight "pressure plate."

Simultaneous Slimming of Bearings and Housings: A smaller flange means supporting bearings can be selected in smaller sizes, subsequently driving the compact design of the entire joint housing and support structure, creating a virtuous cycle of "size-weight" reduction.

Enhanced Modular Joint Performance: For highly integrated modular joints, the DAOLER® spacer provides a standard, reliable, compact zero-backlash connection interface, enabling core components like motors, reducers, and sensors to be integrated with maximum density, ultimately creating joint modules with unprecedented power density.

Case Study Insight: A collaborative robot manufacturer, in its sixth-generation product, switched the output connection from splines to the DAOLER® Diamond Friction Spacer solution. While increasing output torque by 15%, they successfully reduced the joint housing radial size by 20% and weight by over 15%, achieving a leap in product competitiveness.

Conclusion

The DAOLER® Diamond Friction Spacer is not just a component; it is a key technology propelling the evolution of robot design paradigms. It liberates engineers from the traditional mindset of "ensuring safety by increasing size," ushering in a new era of "optimizing design by enhancing material properties." On the journey towards极致 compact, precise, and reliable robots, DAOLER® is becoming that indispensable "core engine."

请先 登录后发表评论 ~