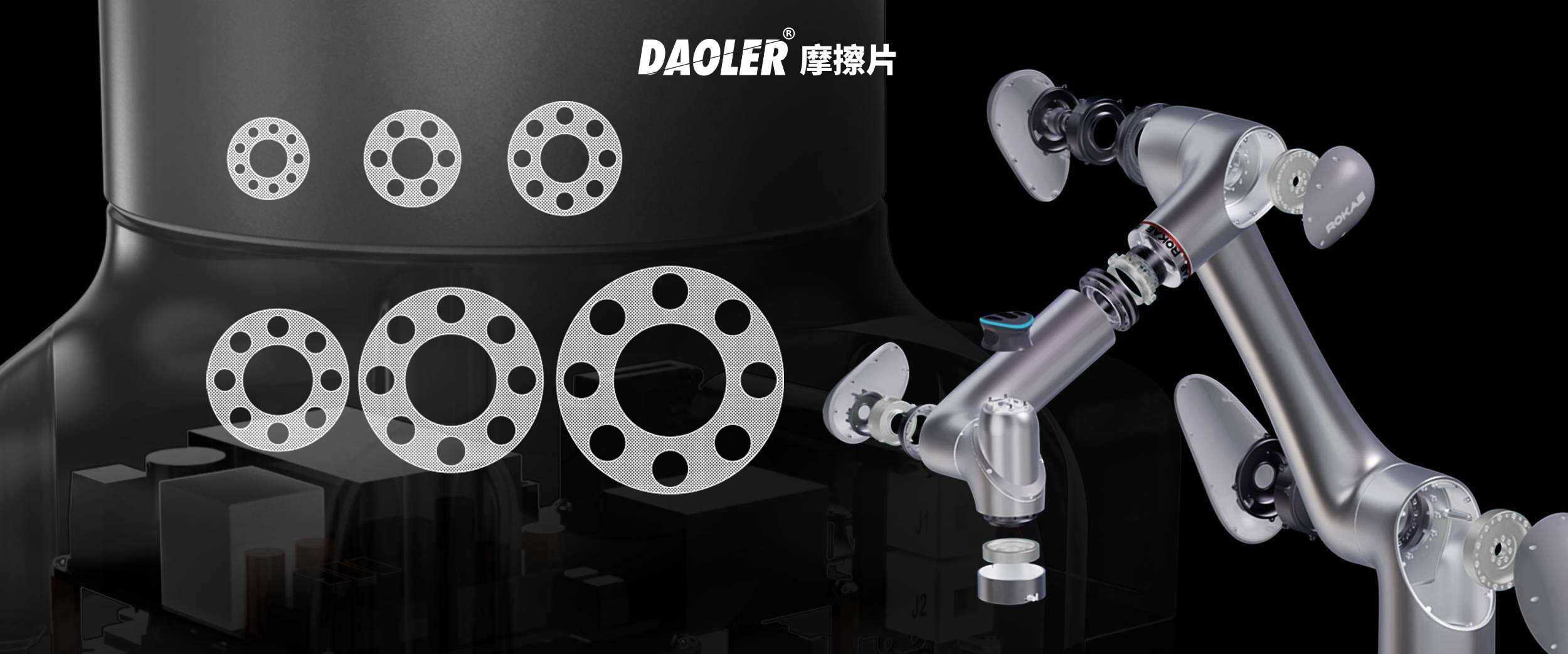

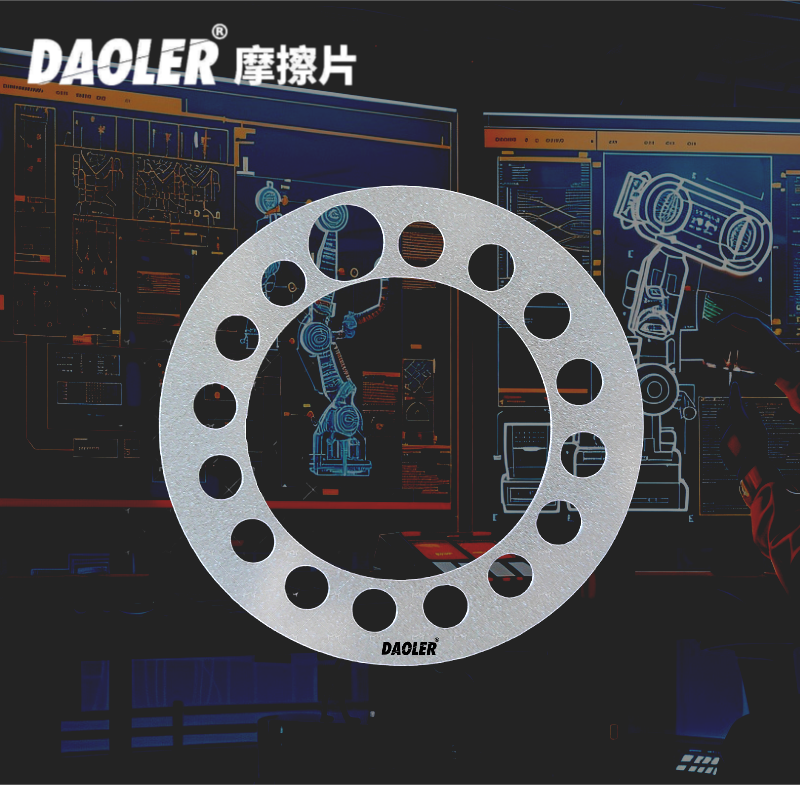

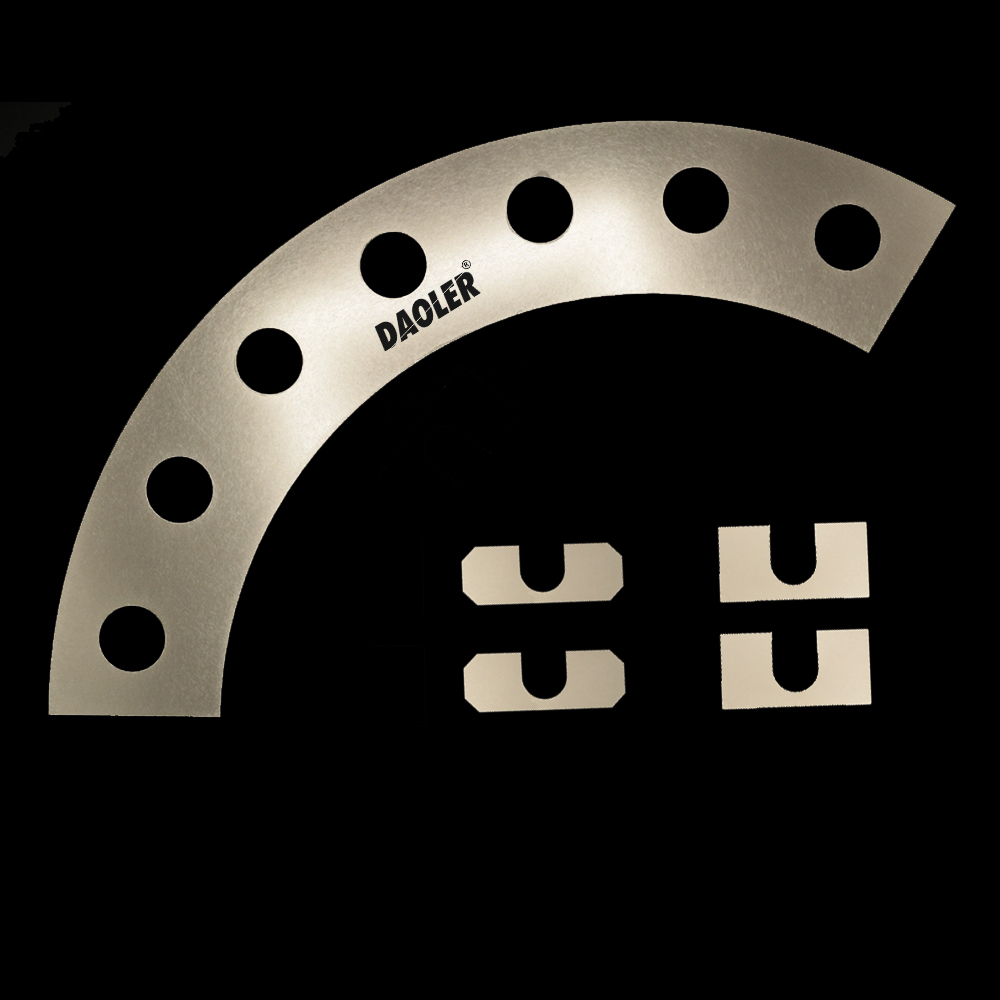

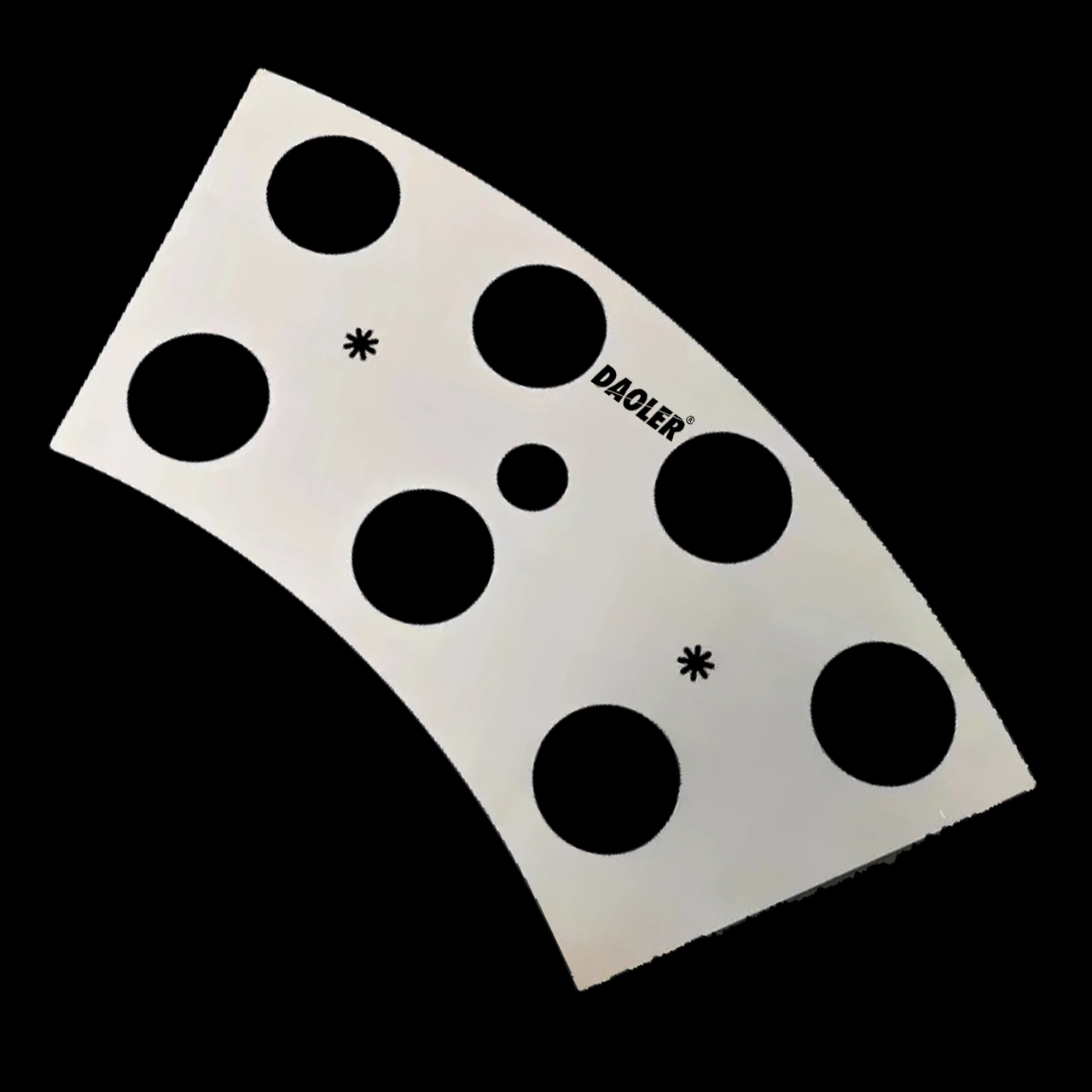

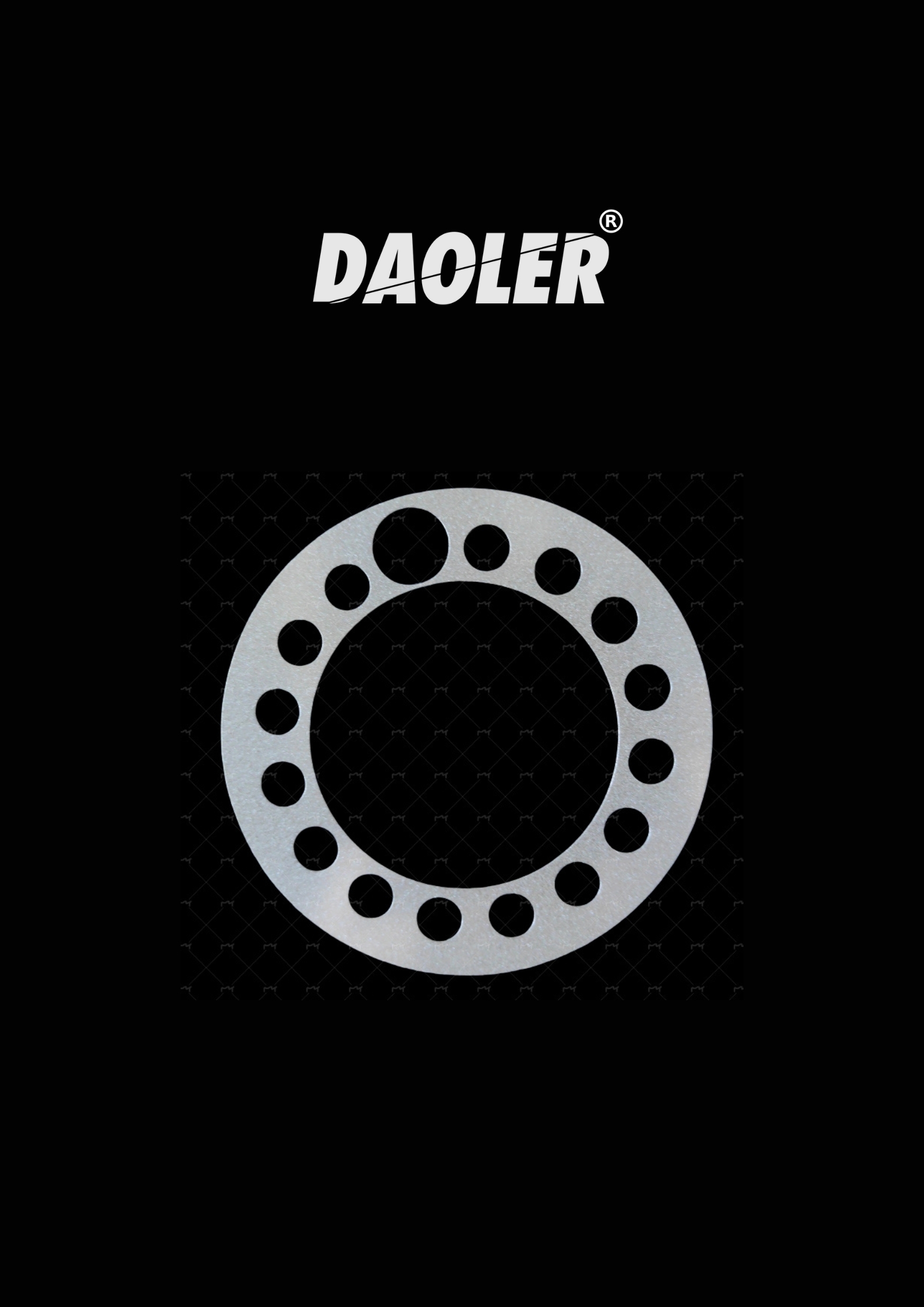

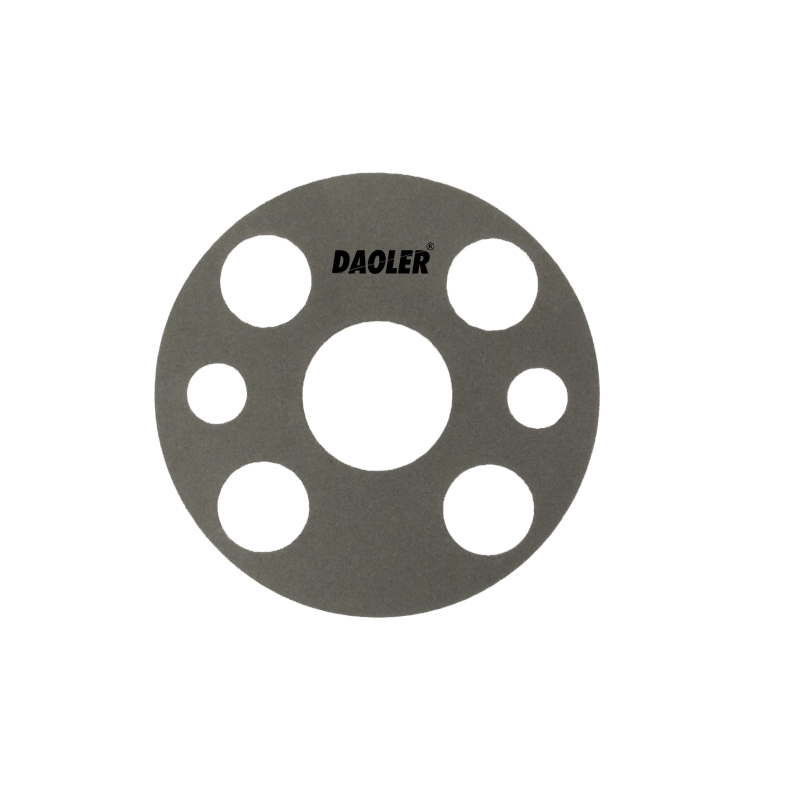

DAOLER® 官方 中国智造 加强连接 提升5倍静摩擦系数 超薄高摩擦垫片

品牌定位: DAOLER® —— 专注于高摩擦防松解决方案的专家。

核心技术:

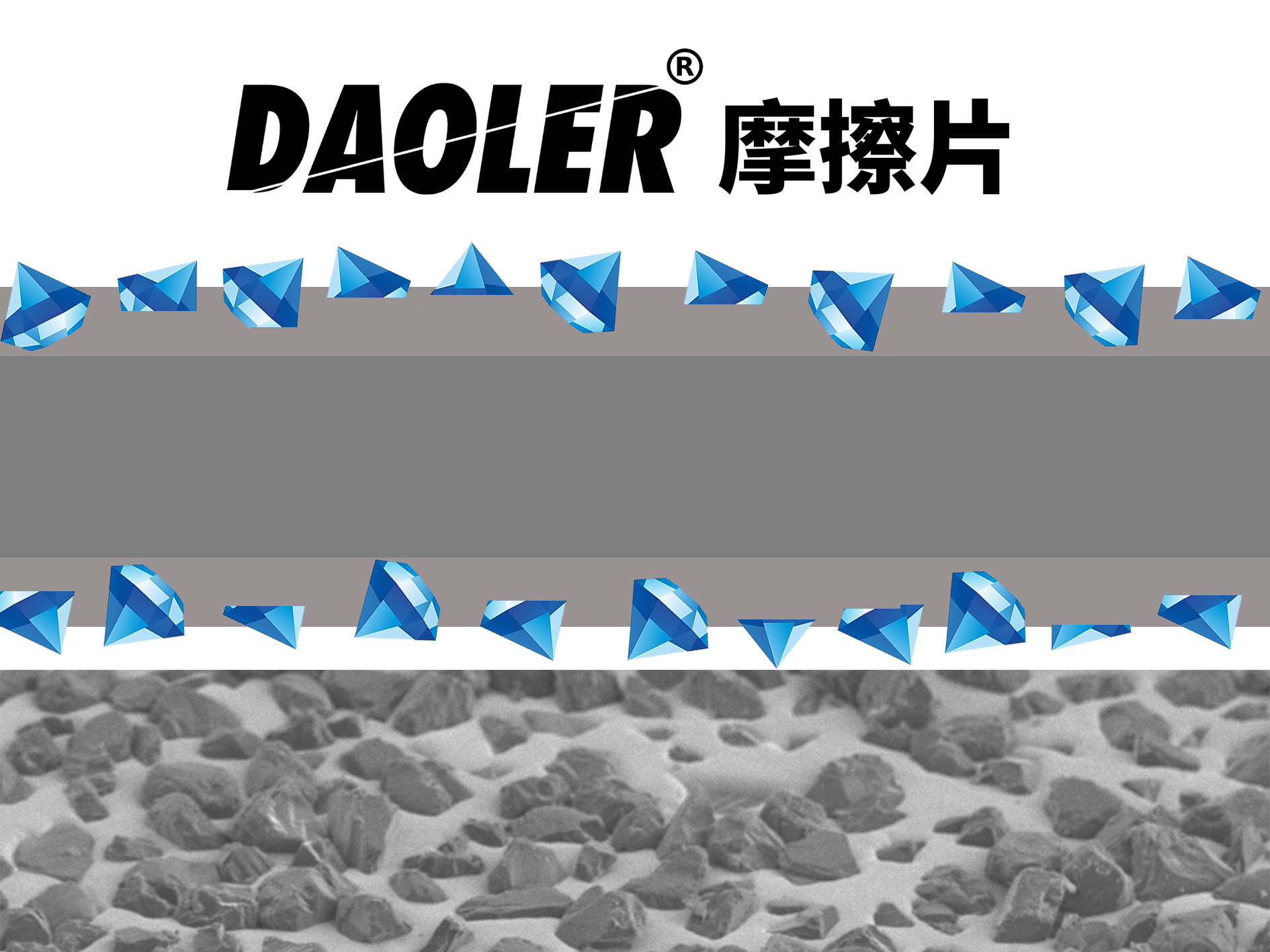

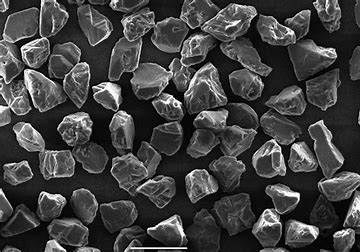

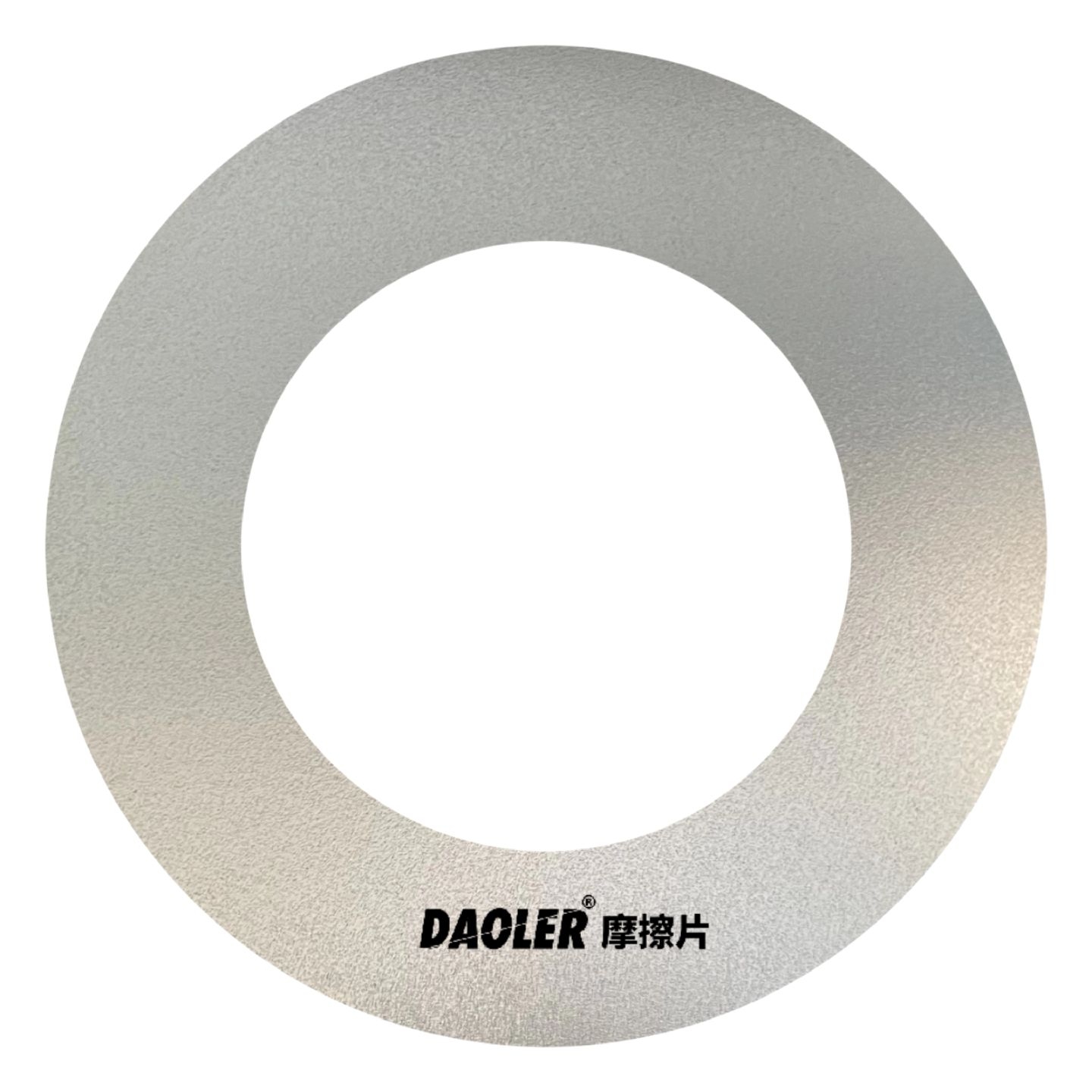

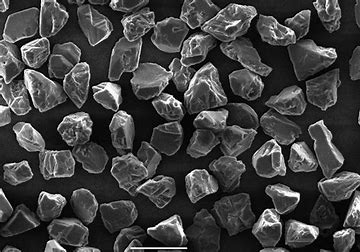

采用镍镀钢作为基材,并通过专利技术将微米级金刚石颗粒部分嵌入其中,形成兼具极高摩擦系数与卓越耐久性的摩擦表面。

核心特点:

极致摩擦系数:表面嵌入的金刚石颗粒是自然界中摩擦系数最高的物质之一,能提供远超普通涂层的防松脱和抗滑动能力。

坚固耐用:镍镀钢基材提供了优异的机械强度和刚性,确保垫片在高压下不变形。金刚石颗粒的嵌入结构避免了涂层脱落问题,寿命更长。

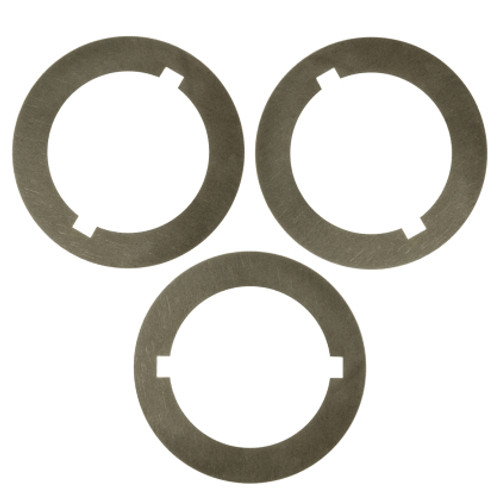

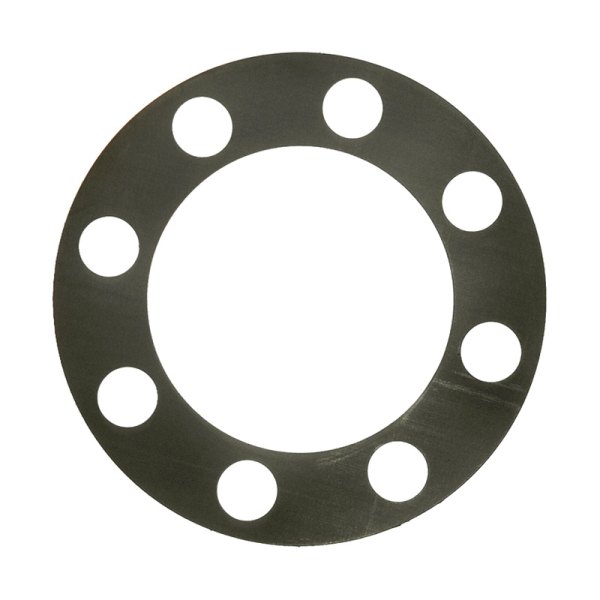

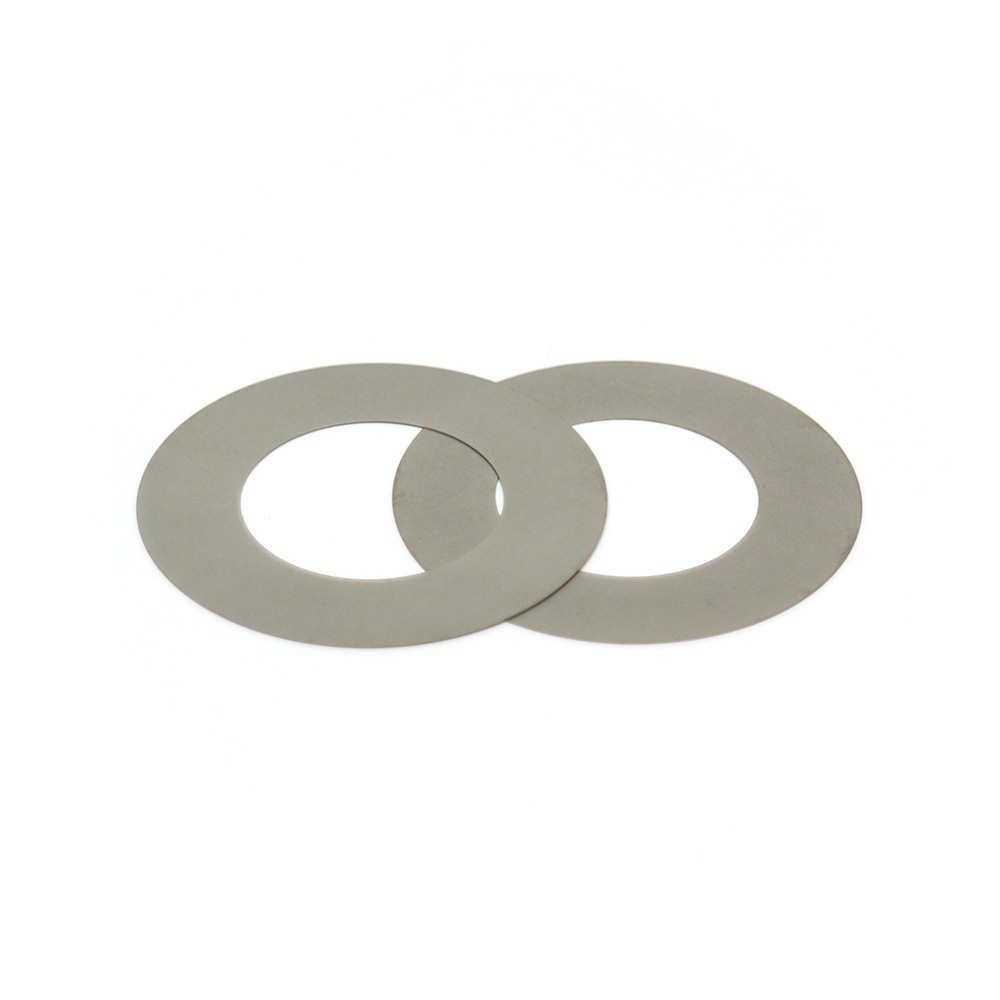

超薄轻量:垫片厚度极薄,几乎不增加连接点的体积和重量,是实现精密设备轻量化设计的理想选择。

轻度耐腐蚀:镍镀层为钢基体提供了有效的保护,能够应对一般工作环境中的潮湿和腐蚀。

稳定可靠:金属基材确保了摩擦系数在不同温度和压力下保持稳定,性能不受蠕变或老化影响。

典型应用领域:

风能发电:风机主轴、齿轮箱、叶片调节机构等关键部位的高强度防松。

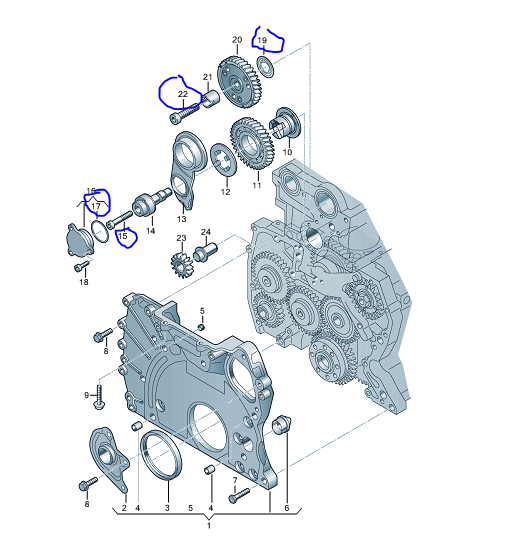

汽车制造:发动机悬置、底盘连接、刹车系统、传动系统等对安全要求极高的振动部位。

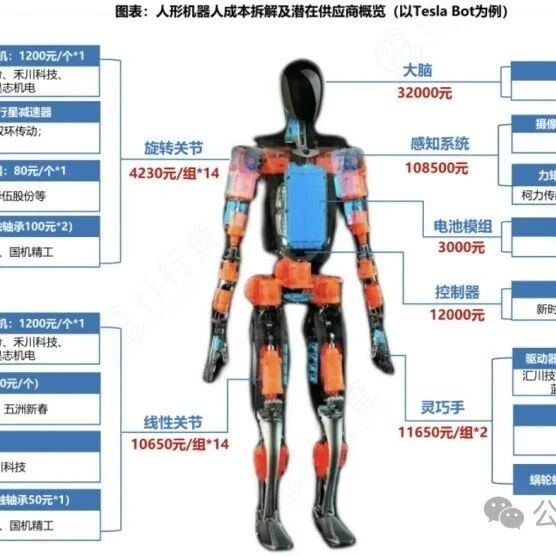

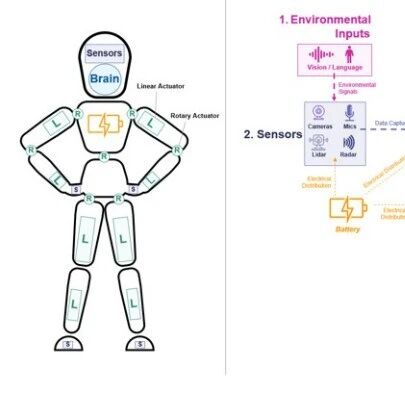

工业机器人:机器人关节、谐波减速器输出端、直线导轨等需要高精度、零背隙的紧固场景。

航空航天:对重量和可靠性有极致要求的飞行器控制系统、发动机部件、星载设备等。

精密仪器:光学平台、医疗设备、半导体制造设备等需要超强防微动能力的场合。

客户价值:

提升产品可靠性:从根本上解决振动环境下的紧固件松动问题。

简化设计:可替代部分复杂的锁紧机构,降低设计和制造成本。

维护简便:可重复使用(在一定次数内),便于设备现场维护与调试。

合作模式:

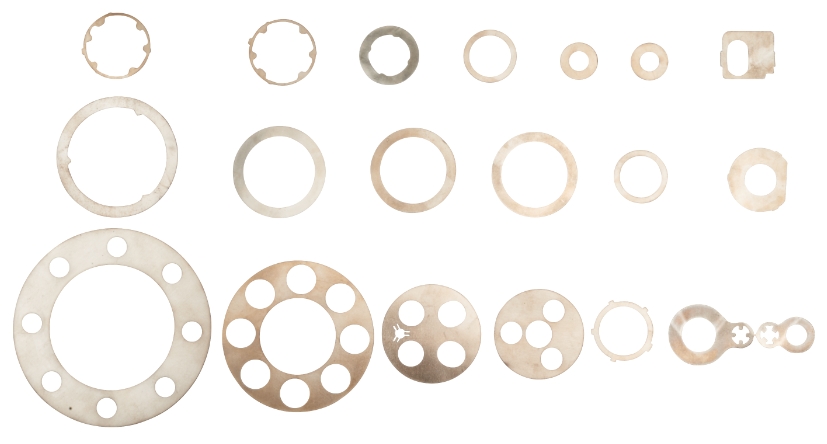

我们支持按客户需求定制(如特定尺寸、形状、摩擦系数要求),并可申请样品试用,以便您在实际应用中验证其卓越性能。热线电话:+86 18866577333

Brand Positioning: DAOLER® – The Expert in High-Friction Anti-Loosening Solutions.

Core Technology:

Utilizes a nickel-plated steel substrate and embeds micron-sized diamond particles via proprietary technology, creating a friction surface that combines an extremely high coefficient of friction with exceptional durability.

Key Features:

Extreme Coefficient of Friction: The embedded diamond particles, among the materials with the highest natural coefficient of friction, provide far superior anti-loosening and anti-slip capability compared to ordinary coatings.

Robust and Durable: The nickel-plated steel substrate offers excellent mechanical strength and rigidity, ensuring the washer does not deform under high pressure. The embedded structure of the diamond particles prevents coating delamination, resulting in a longer service life.

Ultra-Thin and Lightweight: The washers are exceptionally thin, adding minimal volume and weight to the connection point, making them ideal for the lightweight design of precision equipment.

Mild Corrosion Resistance: The nickel plating provides effective protection for the steel base, suitable for resisting moisture and corrosion in general working environments.

Stable and Reliable: The metal substrate ensures a stable coefficient of friction under varying temperatures and pressures, with performance unaffected by creep or aging.

Typical Application Areas:

Wind Power Generation: High-strength anti-loosening for critical areas like main shafts, gearboxes, and blade adjustment mechanisms.

Automotive Manufacturing: Vibration-prone locations with high safety requirements, such as engine mounts, chassis connections, brake systems, and transmission systems.

Industrial Robotics: Fastening scenarios demanding high precision and zero backlash, like robot joints, harmonic reducer outputs, and linear guides.

Aerospace: Applications with extreme demands for weight and reliability, such as flight control systems, engine components, and satellite-borne equipment.

Precision Instruments: Occasions requiring superior anti-micromotion capability, like optical platforms, medical devices, and semiconductor manufacturing equipment.

Customer Value:

Enhances Product Reliability: Fundamentally resolves fastener loosening issues in vibrational environments.

Simplifies Design: Can replace some complex locking mechanisms, reducing design and manufacturing costs.

Eases Maintenance: Reusable (within a certain number of cycles), facilitating on-site equipment maintenance and debugging.

Cooperation Model:

We support customization according to client needs (e.g., specific dimensions, shapes, coefficient of friction requirements) and offer sample applications for testing, allowing you to verify its exceptional performance in practical applications.

请先 登录后发表评论 ~